What Makes 6063 Aluminum Alloy Plates the Preferred Choice in Modern Manufacturing?

Table of Contents

- Key Properties of 6063 Aluminum Alloy Plates That Enhance Manufacturing Efficiency

- Top Industries Benefiting from the Use of 6063 Aluminum Alloy Plates

- Comparative Analysis: 6063 Aluminum Alloy vs. Other Aluminum Alloys in Manufacturing

- Sustainability and Environmental Benefits of Using 6063 Aluminum Alloy Plates

- Future Trends in Manufacturing with 6063 Aluminum Alloy Plates

- FAQS

- Conclusion

- Related Posts

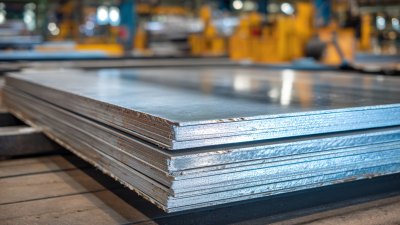

In today's fast-moving manufacturing world, choosing the right materials can really make or break the quality and efficiency of production. Among all the aluminum alloys out there, 6063 Aluminum Alloy Plates have become pretty popular—especially when you need something that's easy to extrude and has a nice surface finish. Industry reports are showing that the global aluminum market is expected to grow at around 6.6% annually from 2020 to 2025. People also highlight 6063 for its versatility and lightweight nature, which makes it a favorite in industries like aviation and shipbuilding. Here at Shanghai Miandi Metal Group Co., Ltd., we offer a wide range of aluminum products, including the 6063 alloy, to meet all kinds of manufacturing needs. Honestly, with its durability, good looks, and ease of working with, 6063 aluminum has become pretty much a go-to material in modern manufacturing—it really just checks all the boxes.

Key Properties of 6063 Aluminum Alloy Plates That Enhance Manufacturing Efficiency

6063 aluminum alloy sheets have become super popular these days in manufacturing because of their amazing properties that really help boost efficiency. One of the things folks love about 6063 is how easy it is to work with—like, you can shape it into all sorts of complex forms without worrying about losing strength. That’s a huge plus in industries where creative and flexible designs are a must, since it opens up a lot of cool possibilities tailored to each project.

Plus, this alloy is pretty tough against rust and corrosion, which means products made from 6063 last a long time and stay durable. That’s why industries like automotive and construction are diving into this material more and more—they want something that doesn’t require a ton of maintenance and still performs well over the years. This definitely helps cut down on costs in the long run, making manufacturing processes more efficient.

**A couple of tips:** When you’re choosing 6063 aluminum sheets for your project, it’s a smart idea to think about the specific mechanical properties you need. That way, you get the best performance without wasting material. Also, don’t forget to talk to your supplier about the best finishes for these plates—they can seriously change how your final product looks and works, depending on what you’re aiming for.

Top Industries Benefiting from the Use of 6063 Aluminum Alloy Plates

Have you noticed how 6063 aluminum alloy sheets are really gaining popularity across different industries? It's pretty interesting! One of the big areas using these plates is construction. Thanks to its awesome extrusion properties, 6063 is just perfect for building things like window frames, doors, and even more decorative architectural features. Plus, its resistance to corrosion combined with a nice, clean look makes it a go-to choice for both commercial buildings and homes. It’s like getting durability and good looks all in one.

On the flip side, the automotive industry is also tapping into what 6063 has to offer. Since it’s lightweight, it helps make vehicles more fuel-efficient, but without sacrificing strength—that’s a pretty sweet deal! You’ll find these plates used in dashboard supports, support beams, and other parts inside the car that need to be tough but light. And because the alloy is so malleable, manufacturers can shape it into pretty complex forms without losing its strength. Honestly, it’s quite versatile.

**A little tip:** When you’re choosing 6063 aluminum for your project, think about the finish you want and whether surface treatments could boost its performance. Also, double-check that your alloy meets the industry standards for what you’re making—that way, you’ll get the best results and ensure everything holds up over time.

Benefits of 6063 Aluminum Alloy Plates in Modern Manufacturing

Comparative Analysis: 6063 Aluminum Alloy vs. Other Aluminum Alloys in Manufacturing

When it comes to manufacturing, picking the right aluminum alloy is pretty important if you want your end product to perform well and last long. Out of all the options out there, 6063 aluminum really stands out. That’s mainly because of its amazing properties. Compared to other alloys like 6061 or 7075, 6063 has a smoother surface finish and is much easier to extrude, which makes it perfect for things like windows, doors, and other architectural stuff. Plus, it looks good and is super versatile when it comes to shaping and fabrication. That’s a huge plus when you're aiming for both strength and style in building projects.

On top of that, if you look at the mechanical properties, 6063 strikes a nice balance between being strong and resistant to corrosion. Now, 6061 is stronger overall, but 6063 has better workability and weldability — which can be a game-changer if you're doing detailed designs or need seamless joins. And unlike 7075, which is more about high strength per weight ratio and often found in aerospace or racing parts, 6063 is more about conductivity, aesthetic finish, and ease of fabrication. All these things make it a go-to choice, especially when you need something that’s both functional and good-looking without sacrificing ease of use or appearance.

Sustainability and Environmental Benefits of Using 6063 Aluminum Alloy Plates

You know, the 6063 aluminum alloy plates have really been gaining traction in manufacturing these days. People love them not just because they work well, but also because they're pretty eco-friendly. As more companies aim to cut down their carbon footprint, that 6063 alloy, with its great extrudability and smooth surface finish, is becoming a popular choice. I read a recent report from the Aluminum Association — it says recycling aluminum can save up to 95% of the energy you'd need to make it from scratch. That’s a huge deal when it comes to being greener. Recycling 6063 aluminum isn't just good for the environment; it also helps cut down on waste, which is great for building a circular economy.

Oh, and there's more. Because it's lightweight but super strong, 6063 alloy plates are perfect for all kinds of industries—think aviation, aerospace, even shipbuilding. Switching to aluminum can really lighten up products. For example, the International Aluminum Institute mentions that swapping steel out for aluminum on vehicles can cut weight by about 15-25%. That means better fuel economy and fewer greenhouse gases. Here at Shanghai Miandi Metal Group Co., Ltd., we're proud to offer a bunch of aluminum products, including 6063 alloy plates. We want our customers to enjoy all these benefits—making their products more efficient and eco-conscious at the same time.

Future Trends in Manufacturing with 6063 Aluminum Alloy Plates

You know, these days, 6063 aluminum alloy sheets are kind of becoming a big deal in modern manufacturing. It’s like everyone’s looking for something that’s both efficient and eco-friendly. As industries shift towards lighter materials that still pack a punch when it comes to strength, 6063 aluminum has really sort of taken center stage. You’ll see it popping up everywhere — from building frameworks to parts in cars. It’s got this great knack for extrusion and doesn’t rust easily, so manufacturers can really get creative and come up with stuff that lives up to today’s tough engineering standards.

Looking ahead, I think the future’s pretty bright for 6063 aluminum sheets. With new recycling tech and the push for greener practices, repurposing aluminum is only going to grow in importance. As companies try to cut down on their carbon footprints, the fact that 6063 is easily recyclable makes it a no-brainer — it’s good for the planet and doesn’t mean skimping on quality. Plus, with smarter manufacturing tech becoming more common, making customized, high-quality 6063 products is getting easier and faster. All of this really opens doors for innovation, allowing different industries to push the boundaries of design and application in ways we couldn’t have imagined before.

What Makes 6063 Aluminum Alloy Plates the Preferred Choice in Modern Manufacturing?

| Property | Value | Importance in Manufacturing |

|---|---|---|

| Density | 2.70 g/cm³ | Lightweight, reducing overall product weight. |

| Tensile Strength | 240 MPa (34,800 psi) | Ensures durability and resistance to deformation under stress. |

| Corrosion Resistance | Excellent | Increases longevity of products in various environments. |

| Thermal Conductivity | 200 W/m·K | Facilitates heat dissipation in thermal applications. |

| Electrical Conductivity | 61% IACS | Suitable for electrical applications where conductivity is crucial. |

| Machinability | Good | Streamlines manufacturing processes, reducing production time. |

FAQS

: The construction and automotive manufacturing industries are two primary sectors benefiting from 6063 aluminum alloy plates due to their unique properties.

It is preferred for its excellent extrusion capabilities, corrosion resistance, and aesthetic appeal, which allow for durable and visually pleasing designs.

The lightweight nature of 6063 aluminum alloy contributes to fuel efficiency while maintaining structural integrity, making it ideal for automotive components.

Applications include dashboard structures and support beams, where the alloy's malleability allows for complex shapes without sacrificing strength.

Factors such as desired finish and potential surface treatments should be considered, as these can enhance the alloy’s properties for specific applications.

The growing emphasis on eco-friendly practices and advancements in recycling technologies enhance the demand for 6063 aluminum due to its recyclability and ability to support a sustainable supply chain.

The integration of smart manufacturing technologies will optimize production processes, allowing for more efficient and responsive customization of 6063 aluminum products to meet market needs.

Its lightweight nature, excellent extrusion properties, and corrosion resistance make 6063 aluminum ideal for a variety of applications in modern manufacturing.

The aesthetic appeal of 6063 aluminum alloy contributes to appealing designs in both commercial and residential projects, making it a popular choice for architects and builders.

Trends prioritizing efficiency, sustainability, and the use of lightweight materials that do not compromise on strength are influencing the increased adoption of 6063 aluminum alloy plates.

Conclusion

When it comes to modern manufacturing, 6063 Aluminum Alloy Plates really stand out because of their amazing features that boost production efficiency. They’re known for being super easy to work with, resistant to corrosion, and lightweight — all reasons why industries like aviation, aerospace, and shipbuilding love them. Plus, fabricating these plates is pretty straightforward, which makes it possible to create detailed designs and complex parts without much hassle. That’s why lots of manufacturers prefer using them.

If you compare 6063 aluminum plates to other types of aluminum alloys, you’ll see they tend to perform better in many ways — especially when it comes to eco-friendliness and sustainability. As the industry shifts gears toward more environmentally conscious practices, these plates not only help streamline manufacturing but also align perfectly with future trends focused on sustainability. Here at Shanghai Miandi Metal Group Co., Ltd., we understand just how important these plates are for current applications, and we’re proud to offer a wide range of aluminum solutions tailored to meet the needs of different sectors.

Related Posts

-

Top Strategies for Sourcing Affordable 6061 T6 Aluminum in the Global Market

-

The Ultimate Guide to Choosing the Right 6061 T651 Plate for Your Manufacturing Needs

-

Navigating Import and Export Certifications for Best 6061 Aluminum Alloy Products in Global Markets

-

Ultimate Guide to Sourcing Customized 6082 T6 Aluminum Bars for Global Buyers

-

Unique Applications of China Aluminum Forging in Modern Industries

-

Unlocking the Potential of Aluminum Alloy Plates for Innovative Industrial Applications

Blog Tags: