Confronting the Aluminum Shortage Crisis of 2024: Key Challenges for the Manufacturing Sector

Table of Contents

- The Global Aluminum Shortage: An Overview of 2024 Factors Impacting Supply

- Impact of Strong Demand from Electric Vehicle Production on Aluminum Availability

- Economic Ramifications: Rising Costs for Aluminum in Manufacturing Processes

- Supply Chain Disruptions: Key Regions Affected by the Aluminum Shortage Crisis

- Sustainable Alternatives: Innovations in Material Substitutes for Aluminum Components

- Strategic Responses: How Manufacturers Are Adapting to the Aluminum Deficit

- Unlocking Versatility: Exploring the Benefits of Ready Stock Aluminum Sheets and Plates for 2024 and Beyond

- FAQS

- Conclusion

- Related Posts

As we deal with the ongoing Aluminum Shortage in 2024, the manufacturing world is hitting some pretty tough spots — challenges we haven't really seen before. It’s definitely a situation that needs our quick action and careful planning. This shortage isn’t just a small hiccup; it touches a bunch of different industries.

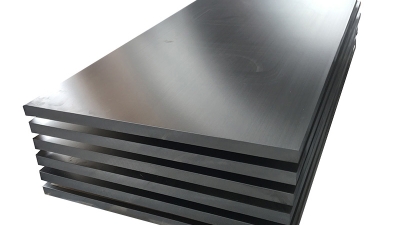

Take companies like Shanghai Miandi Metal Group Co., Ltd., for example — we’re in the business of distributing all kinds of aluminum products, from the 1000 series to the 8000 series. Our inventory includes aluminum plates, rods, flats, angles, and tubes, which are super important for sectors like aviation, aerospace, and shipbuilding.

Facing this crisis means manufacturers really need to take a hard look at their supply chains, tweak their procurement strategies, and get creative with solutions to keep things moving smoothly despite the shortage. In this blog, I’ll walk you through some key challenges and proactive tips to help your business stay afloat in the rollercoaster ride of the aluminum market in 2024.

Take companies like Shanghai Miandi Metal Group Co., Ltd., for example — we’re in the business of distributing all kinds of aluminum products, from the 1000 series to the 8000 series. Our inventory includes aluminum plates, rods, flats, angles, and tubes, which are super important for sectors like aviation, aerospace, and shipbuilding.

Facing this crisis means manufacturers really need to take a hard look at their supply chains, tweak their procurement strategies, and get creative with solutions to keep things moving smoothly despite the shortage. In this blog, I’ll walk you through some key challenges and proactive tips to help your business stay afloat in the rollercoaster ride of the aluminum market in 2024.

The Global Aluminum Shortage: An Overview of 2024 Factors Impacting Supply

So, looking at the global aluminum scene in 2024, it’s been a bit of a rollercoaster. There have been quite a few disruptions that are really putting a strain on manufacturers. A big reason for the ongoing aluminum shortage is the tight supply of alumina, along with rising geopolitical tensions and some major shipping hiccups. All these factors together have made prices jump around quite a bit throughout the year. People are saying that, in the short run, we’ll probably see more price swings, but looking ahead, the overall outlook still seems pretty positive — mainly because demand is expected to pick up across different industries.

On top of that, in Asia, the market for aluminium alloy ingots has seen prices climb pretty noticeably. That’s mainly because scrap prices are up and the market vibe is looking pretty optimistic. Meanwhile, in the US, aluminium premiums have shot up after some tariff changes, which only makes trading more complicated. As manufacturers try to deal with all these hurdles, it’s clear that strategies like smart sourcing, innovative recycling methods, and exploring new supply routes are going to be key in managing the aluminum shortage mess we're in for 2024.

Confronting the Aluminum Shortage Crisis of 2024: Key Challenges for the Manufacturing Sector

| Factor | Impact on Supply | Projected Shortage (Metric Tons) | Region Most Affected |

|---|---|---|---|

| Increased Demand in Construction Sector | Higher consumption of aluminum for infrastructure projects | 1,200,000 | North America |

| Supply Chain Disruptions | Delays in raw material transportation affect production | 800,000 | Europe |

| Geopolitical Tensions | Sanctions and tariffs restrict access to aluminum | 600,000 | Asia |

| Environmental Regulations | Stricter laws lead to reduced production capacity | 500,000 | Australia |

| Technological Limitations | Inability to scale up recycling technologies fast enough | 300,000 | South America |

Impact of Strong Demand from Electric Vehicle Production on Aluminum Availability

So, here’s the deal: with 2024 rolling in, the world’s really feeling a serious aluminum shortage. It’s kind of a big headache for manufacturers because the demand for aluminum has skyrocketed — mostly thanks to the booming electric vehicle (EV) industry. Electric cars need tons of lightweight aluminum for their bodies and parts, and that’s got everyone competing fiercely for this key resource. This sudden jump in demand isn’t just tightening supply chains; it’s also making companies rethink how they source their materials.

At Shanghai Miandi Metal Group Co., Ltd., we’re right in the thick of things. We supply a wide range of aluminum products — from 1000 to 8000 series, including plates, rods, and tubes — and serve industries like aerospace, aviation, and shipbuilding. As the EV market continues to grow, making sure we have a reliable source of quality aluminum becomes more and more critical to keep production running smoothly across the board. We’re working hard to adapt, build stronger partnerships, and come up with innovative solutions to meet the shifting needs of our customers in such a tricky environment. It’s definitely a challenging time, but we’re doing our best to navigate through it.

At Shanghai Miandi Metal Group Co., Ltd., we’re right in the thick of things. We supply a wide range of aluminum products — from 1000 to 8000 series, including plates, rods, and tubes — and serve industries like aerospace, aviation, and shipbuilding. As the EV market continues to grow, making sure we have a reliable source of quality aluminum becomes more and more critical to keep production running smoothly across the board. We’re working hard to adapt, build stronger partnerships, and come up with innovative solutions to meet the shifting needs of our customers in such a tricky environment. It’s definitely a challenging time, but we’re doing our best to navigate through it.

Economic Ramifications: Rising Costs for Aluminum in Manufacturing Processes

The aluminum shortage in 2024 is really throwing a wrench into the manufacturing world, especially for industries that depend heavily on aluminum. As demand keeps climbing and supply chains get tighter, we've seen aluminum prices spike—by around 30% over the past year, according to recent reports. That bump in price isn't just a headline; it actually affects how much it costs to make things, which eventually leads to higher prices for consumers too.

Now, companies like Shanghai Miandi Metal Group Co., Ltd. are playing a pretty crucial role here. They're handling a wide range of aluminum products—from the common 1000 series to the more specialized 8000 series, including plates, rods, and tubes. For industries like aviation, aerospace, and shipbuilding, finding good quality aluminum at a fair price is more important than ever. Just last year, the aerospace sector was expected to use about 1.5 million tons of aluminum—that’s a huge number that shows how much demand there is. The key for businesses now is being able to adapt—by managing supply chain issues and sticking to quality—to stay afloat during these tricky times.

Basically, those who can keep things running smoothly and secure reliable supplies are going to have a real edge in this unpredictable economy.

Supply Chain Disruptions: Key Regions Affected by the Aluminum Shortage Crisis

So, the aluminum shortage that's been hitting hard in 2024 has really caused quite a stir across different manufacturing industries. A lot of it comes down to supply chain hiccups that are hitting key regions around the world.

Places like China, Canada, and Russia—big players when it comes to aluminum supplies—are dealing with all kinds of issues, from environmental rules and labor strikes to rising geopolitical tensions. These problems aren’t just slowing down production; they’re also threatening the stability of global markets that depend on aluminum for their day-to-day operations.

Places like China, Canada, and Russia—big players when it comes to aluminum supplies—are dealing with all kinds of issues, from environmental rules and labor strikes to rising geopolitical tensions. These problems aren’t just slowing down production; they’re also threatening the stability of global markets that depend on aluminum for their day-to-day operations.

And it’s not just about where the aluminum comes from. There’s also the fact that industries like automotive and construction are demanding more than ever, which only ramps up the complexity of the crisis. As companies scramble to get their hands on enough material, prices have shot up, creating a chain reaction that affects everyone downstream. In response, many businesses are reevaluating their sourcing plans—some are even considering switching to alternative materials or looking more closely at regional suppliers to reduce risks. It’s pretty clear that innovation and strategic planning are more important than ever if they want to keep things running smoothly and meet their commitments in this pretty uncertain landscape.

Sustainable Alternatives: Innovations in Material Substitutes for Aluminum Components

With the aluminum shortage crisis looming in 2024, the manufacturing world is definitely feeling the heat. There's been a huge spike in demand for aluminum products—stuff like aluminum plates, rods, and tubes—especially in industries like aviation and aerospace. I mean, a recent market analysis predicts that by 2025, global aluminum consumption could top 80 million metric tons. That’s a serious wake-up call for manufacturers to start looking into sustainable alternatives before things get really tight.

People are exploring new material options that could replace aluminum parts. Some promising research is showing that advanced composites, like carbon fiber reinforced polymers, can match aluminum in strength and weight, but with the bonus of better resistance to corrosion and heat. These materials are already making their way into sectors that traditionally leaned heavily on aluminum. Experts expect the market for composites to grow by over 10% annually over the next five years. As companies like Shanghai Miandi focus more on sustainability, this real shift towards new materials might totally change how supply chains work in manufacturing down the line.

Aluminum Shortage Crisis: Key Challenges for the Manufacturing Sector

This chart illustrates the global aluminum demand and production trends from 2020 to 2024. The ongoing aluminum shortage presents significant challenges for the manufacturing sector, highlighting the necessity for sustainable alternatives and innovations in material substitutes.

Strategic Responses: How Manufacturers Are Adapting to the Aluminum Deficit

So, here’s the deal with the aluminum shortage in 2024—it's really shaking things up for manufacturers. They’re having to rethink their game plan and get a bit creative given how tough the environment has become. With demand for aluminum just skyrocketing across different industries, companies are on the hunt for smart solutions to get around this shortage. A big move has been jumping on the recycling bandwagon—reclaiming scrap aluminum not only helps ease supply chain headaches but also lines up with sustainability goals. By investing in better recycling tech, manufacturers can turn waste into top-notch aluminum products, meaning they don’t have to rely so much on raw aluminum sources anymore.

On top of that, lots of companies are diversifying their supplier networks — basically, working with multiple suppliers in different parts of the world. It’s a smart way to stay flexible and avoid getting caught off guard when disruptions happen. Plus, sourcing locally more often is gaining ground; that cuts down transportation time and costs, which naturally makes things run more smoothly. Some manufacturers are also eyeing alternative materials or developing composite options that could replace aluminum in certain uses. Being adaptable like this is key if they want to stay competitive when the aluminum supply is tight.

Unlocking Versatility: Exploring the Benefits of Ready Stock Aluminum Sheets and Plates for 2024 and Beyond

In an era where efficiency and adaptability are paramount, ready stock aluminum sheets and plates offer a multitude of advantages for industries preparing for the future. The versatility of aluminum materials allows them to be utilized across a wide range of applications, from aerospace to automotive and beyond. With readily available options, businesses can streamline their production processes, reduce lead times, and enhance overall operational efficiency. This is especially crucial as we head into 2024, where agility in supply chains will define competitive success.

Our extensive selection of aluminum plates, including popular grades such as 1060, 2024, 3003, 5052, 5083, 6061, 6063, 6082, and 7075, ensures that we meet the diverse needs of our customers. Each alloy provides unique properties; for instance, 2024 is renowned for its high strength-to-weight ratio, making it ideal for aerospace applications, while 5052 is known for its excellent corrosion resistance, perfect for marine environments. By having these materials readily available, businesses can quickly adapt to shifting demands and maintain momentum in their projects, thus unlocking unparalleled versatility in their operations.

FAQS

: The aluminum shortage in 2024 is primarily driven by unprecedented demand from the electric vehicle (EV) industry, which requires significant amounts of lightweight aluminum for construction.

Aluminum prices have risen by an estimated 30% over the past year due to increased demand and strained supply chains.

Industries heavily reliant on aluminum, such as aviation, aerospace, shipbuilding, automotive, and construction, are the most affected by the aluminum shortage.

Companies are reevaluating their sourcing strategies, looking for alternative materials, and seeking regional suppliers to mitigate risks and secure their material needs.

Shanghai Miandi Metal Group plays a critical role as a distributor of various aluminum products and is adapting to market changes by ensuring a steady supply of high-quality aluminum for different sectors.

Key suppliers of aluminum include China, Canada, and Russia, which are facing challenges such as environmental regulations, labor strikes, and geopolitical tensions.

The aluminum shortage has led to increased production costs that are passed on to consumers, resulting in higher prices for end products.

Companies are focusing on strategic partnerships, optimizing supply chains, and embracing innovation to ensure they can sustain operations amidst the aluminum shortage.

The projected aluminum consumption in the aerospace industry for 2023 is approximately 1.5 million tons.

Maintaining a steady supply of aluminum is crucial for manufacturers to ensure consistent production levels and meet the growing demands across various industries.

Conclusion

The aluminum shortage in 2024 is really throwing a wrench into the manufacturing world. It’s mainly caused by the huge demand from electric vehicle makers and some broader economic factors that are playing a part. Because of this, aluminum prices are climbing, and that’s forcing companies to rethink how they do things. Plus, supply chain issues in key regions make it even tougher to get hold of enough material, leaving manufacturers scratching their heads and looking for solutions.

To deal with the aluminum crunch, businesses are starting to explore alternative materials and new options. It’s an exciting time because these innovations open up fresh possibilities for industries that rely on aluminum, like aerospace, shipbuilding, and more. At Shanghai Miandi Metal Group Co., Ltd., we know how important it is to stay flexible and adapt quickly to these kinds of surprises—especially since we provide a wide range of aluminum products, from the 1000 series all the way up to 8000. We’re committed to supporting our clients through these challenging times—no matter what comes next.

Related Posts

-

Ultimate Guide to Sourcing Customized 6082 T6 Aluminum Bars for Global Buyers

-

Global Market Analysis 2025 for Best Weldable Aluminum Alloy and How to Choose the Right Supplier

-

Unlocking the Potential of Aluminum Alloy Plates for Innovative Industrial Applications

-

Navigating Import and Export Certifications for Best 6061 Aluminum Alloy Products in Global Markets

-

Global Excellence in Aluminum Plate Production Proudly Crafted in China

-

Innovative Solutions for Choosing the Right China Aluminum Plate Manufacturers

Blog Tags: