The Ultimate Guide to Choosing the Right 6061 T651 Plate for Your Manufacturing Needs

Table of Contents

- Understanding the Properties of 6061 T651 Aluminum Plate

- Factors to Consider When Choosing the Right Thickness

- Evaluating the Heat Treatment Process and Its Effects

- Common Applications and Industries Utilizing 6061 T651 Plates

- Cost Considerations and Budgeting for Your Manufacturing Needs

- Recommended Suppliers and Resources for Sourcing 6061 T651 Plates

- Exploring the Advantages of High Quality 7075 T6 T651 Aluminum Sheet for Professional Applications

- FAQS

- Conclusion

- Related Posts

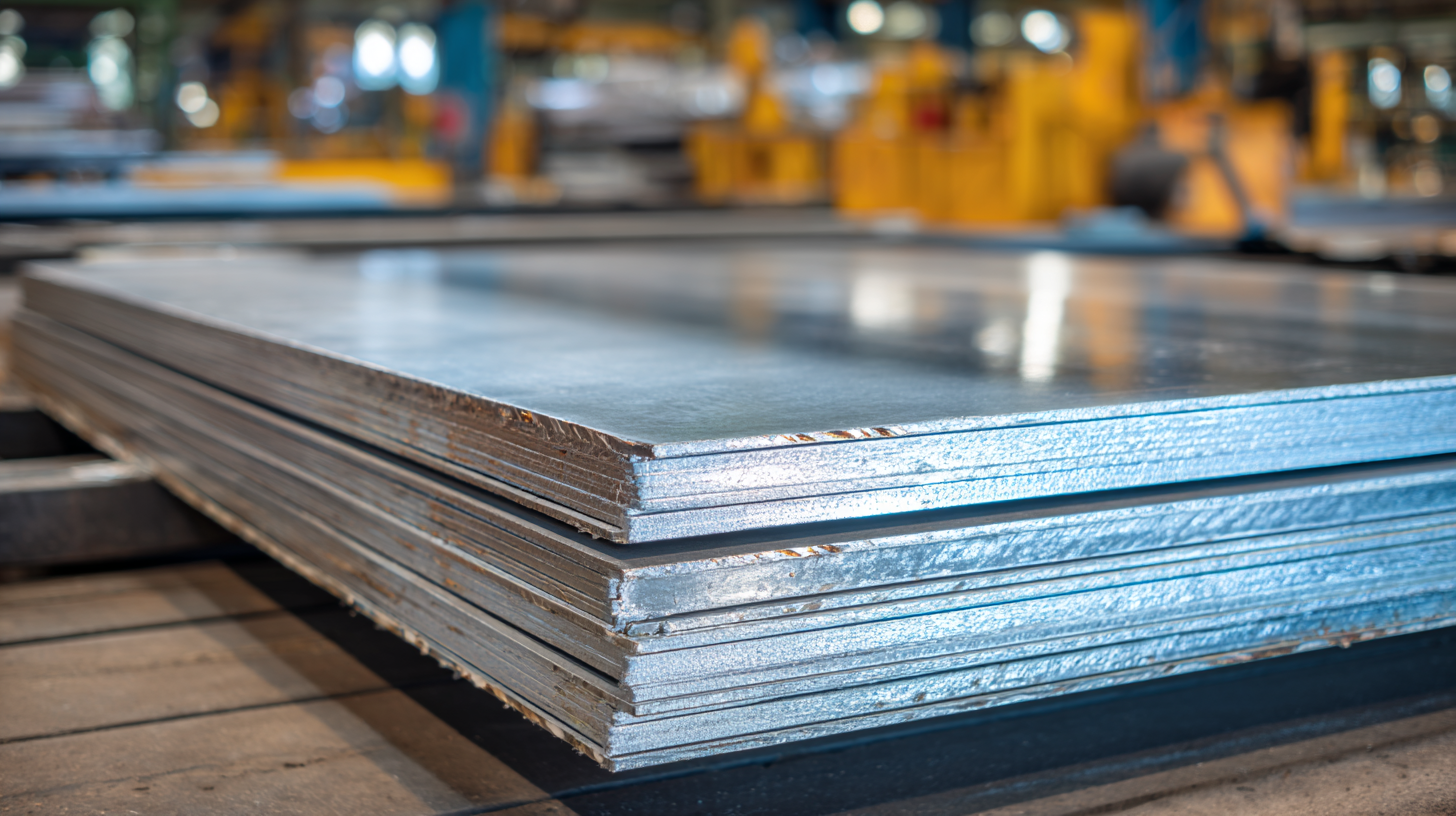

In today’s fast-changing manufacturing world, picking the right aluminum plate is really important if you want your stuff to perform well and last long. This is especially true in really demanding fields like aviation, aerospace, and building ships. One of the most popular choices out there is the 6061 T651 plate — folks love it for its awesome strength combined with light weight and resistance to corrosion. It’s pretty much perfect for tough environments. Industry reports suggest that the global aluminum plate market might hit around $9.9 billion by 2026, which just shows how much interest there is in high-quality aluminum products right now. As a major supplier, Shanghai Miandi Metal Group Co., Ltd. offers a wide range of aluminum options, including that popular 6061 T651 plate. They’re all about making sure manufacturers get their hands on the best materials for their projects. When you’re choosing a factory for 6061 T651 plates, it’s key to find someone who can meet your specific technical and performance needs — that’s what really makes or breaks your project.

Understanding the Properties of 6061 T651 Aluminum Plate

When you're picking out the right 6061 T651 aluminum plate for your project, it’s really helpful to understand what makes this alloy special. It’s known for being strong and easy to weld, which makes it super versatile across different industries. According to the Aluminum Association, it can reach a yield strength of up to 276 MPa—that’s pretty impressive and why it’s often used for structural stuff. Plus, its resistance to corrosion means it holds up well even in tough, moist environments, so it’s a go-to for parts that need to last outdoors or in harsh conditions.

Another thing I should mention is its thermal conductivity—around 170 W/m·K—which is pretty good for helping to manage heat in things like cars and planes. That’s a major perk because it not only helps these parts work better but also plays into the trend of making lighter vehicles. Lighter cars mean better fuel economy, which is a big deal these days. Also, thanks to recent improvements in manufacturing, machining this alloy has become easier and more affordable, making it a solid choice for many industrial applications. Basically, knowing these key properties can really help you make smarter decisions, boosting both how efficient your production is and the quality of your final product.

Factors to Consider When Choosing the Right Thickness

When you're choosing the right thickness for a 6061 T651 plate, it really pays to understand what your specific project needs. Different uses call for different thicknesses — a thicker plate generally offers more strength and durability, but it also adds weight and can bump up the cost. So, it’s pretty important to think about what your project actually requires structurally. For example, if you’re dealing with aerospace parts where weight matters a lot, a thinner plate might do the trick. On the other hand, heavy-duty stuff like construction projects might need something thicker and more rugged.

Also, don’t forget how the thickness could impact the machining and fabrication process. Heavier, thicker plates might need bigger tools or even more advanced machinery, while thinner ones usually work fine with standard equipment. Then there’s the finish and precision to consider — thicker plates can handle deeper machining, but they might make high-precision tasks a bit trickier. Finding the right balance between these factors is key to selecting the best thickness for your 6061 T651 plate, so you end up with a product that hits your performance needs without blowing your budget.

Evaluating the Heat Treatment Process and Its Effects

When you're choosing the right 6061 T651 aluminum plate for your project, it’s super important to understand the heat treatment process behind it. The 'T651' part basically means the material has gone through a specific heat treatment that boosts its mechanical properties—making it stronger and more resistant to corrosion. According to the folks at the Aluminum Association, heat-treated 6061 aluminum can reach yield strengths of over 40 ksi, which is pretty impressive. That makes it a go-to option for tough applications, especially in fields like aerospace and automotive stuff.

Here’s a little tip—always check the thermal history of the alloy you're buying. Since different heat treatments can lead to variations in its properties, it’s a good idea to ask your supplier for clear documentation on what exactly was done. Look for certifications that confirm the material went through the T651 process, including details like how long it was aged and at what temperature.

Also, don’t forget to think about how the heat treatment affects machinability. Sure, those T651 plates are stronger, but they can be a bit more tricky to work with when you're machining them. To get the best results, you'll want to use the right machining settings—like proper feed rates and the right kind of tools—to avoid dulling your tools or messing up the dimensions. It’s worth chatting with your tool supplier to make sure your equipment is up to the task. All in all, a little prep and careful selection can go a long way in making sure your project turns out just right.

The Ultimate Guide to Choosing the Right 6061 T651 Plate for Your Manufacturing Needs

This chart illustrates the effects of various heat treatment processes on the strength of 6061 T651 aluminum plates. The strength values are measured in megapascals (MPa), demonstrating the advantages of each treatment method in manufacturing applications.

Common Applications and Industries Utilizing 6061 T651 Plates

6061 T651 plates are really well-known for being versatile and strong, which is why they’re such a popular pick in different industries. You’ll often find this aluminum alloy used in aerospace, where parts need to handle high stress but still stay lightweight. In fact, a report on the global aerospace aluminum market suggests that the demand for aluminum plates like this is expected to grow at around 6% a year from 2021 to 2026. And it’s no surprise — 6061 T651 is a big part of that growth, thanks to how easy it is to machine and its resistance to corrosion.

Over in the automotive world, these plates are used to make structural parts and chassis because they’re lightweight. That’s a game-changer when it comes to improving fuel efficiency, you know? A recent study by Research and Markets shows that the global automotive aluminum market might hit around $40 billion by 2027, which really shows how much more high-performance aluminum alloys are catching on. And let’s not forget the marine industry — boats and fittings made from 6061 T651 sheets benefit from its ability to resist saltwater corrosion. A Marine Aluminum Market report predicts a steady rise in demand for these materials in the coming years. Overall, it’s pretty clear how crucial the right 6061 T651 plate can be across different sectors—helping them meet their specific needs while taking advantage of its many benefits.

Cost Considerations and Budgeting for Your Manufacturing Needs

When you're choosing a 6061 T651 plate for your project, let's face it—budget really matters. It's super important to get a good handle on how different thicknesses, sizes, and finishes will affect your costs. Trust me, understanding these details helps you stay within your spending limits. Plus, keep an eye on market trends and seasonal shifts—those can really shake up prices more than you’d expect.

Here's a tip: don’t just settle for one quote. Shoot for a few different suppliers so you can compare prices and terms. Also, watch out for promotions or discounts when buying in bulk—that’s often where you can snag some serious savings. Oh, and certifications? Don’t overlook them. Sometimes paying a little extra upfront means you get a higher-quality product that’ll perform better in the long run.

And don’t forget about those extra costs that sneak up on you—like machining, shipping, or waste material during manufacturing. Finding the right balance between quality and cost is key. Sure, that cheaper material might seem tempting, but if it doesn’t meet your specs, you might end up spending more fixing issues later.

Here’s another pro tip: put together a detailed budget that covers everything—materials, processing, shipping, and even potential waste. Stay flexible and be open to swapping out materials if the numbers don’t add up—that way, you can find the best bang for your buck for your project.

Recommended Suppliers and Resources for Sourcing 6061 T651 Plates

When you're choosing the right 6061 T651 aluminum plate for manufacturing, it’s super important to know where to get high-quality materials. If you’re working in industries like aerospace, aviation, or shipbuilding, the specs of that aluminum plate can really make a difference in how well your final product performs and how long it lasts. From what market surveys are telling us, the worldwide market for aluminum plates could hit around $100 billion by 2025 — that’s mainly because demand is soaring across all sorts of sectors. Of course, it’s crucial that suppliers provide plates that tick all the boxes for strict industry standards and certifications. This way, you can count on your materials to deliver top performance and reliability.

Now, take Shanghai Miandi Metal Group Co., Ltd. — they’re pretty well-known as a distributor of aluminum products, including the 6061 T651 plates. They have a pretty extensive lineup, offering everything from 1000 to 8000 series aluminum alloys, so you can find something suitable for pretty much any project. The thing is, the 6061 T651 alloy is especially popular because it resists corrosion really well and welds up nicely, which makes it a go-to choice for many structural parts. When you're sourcing 6061 T651 plates, just make sure your supplier is reputable and can provide materials that match your project’s specific needs. Skimping on that can really impact how smoothly your manufacturing process goes down the line.

Exploring the Advantages of High Quality 7075 T6 T651 Aluminum Sheet for Professional Applications

The 7075 T6 T651 aluminum sheet is renowned in various professional applications for its exceptional performance and versatility. This specific grade of aluminum offers outstanding strength-to-weight ratios, making it an ideal choice for industries that demand high durability without compromising on weight. The T6 and T651 tempers enhance the material's mechanical properties, providing it with superior resistance to fatigue and stress, which is crucial in high-performance sectors such as aerospace and automotive engineering.

One of the significant advantages of using 7075 T6 T651 aluminum sheets is their ability to be machinable and weldable, allowing for various fabrication techniques. With diameters ranging from 1 to 500mm, this aluminum sheet can be easily transformed into customized parts suited to specific project requirements. Its excellent corrosion resistance also means that it can withstand harsh environments, making it a long-lasting solution for components exposed to the elements.

In addition to its physical attributes, the aesthetic appeal of 7075 T6 T651 aluminum sheets cannot be overlooked. Their smooth surface finish makes them ideal for applications where appearance matters, such as in consumer electronics and premium products. By choosing this high-quality aluminum sheet, professionals can ensure that they are investing in a material that not only meets stringent performance expectations but also enhances the overall quality of their final products.

FAQS

: Key factors include the specific manufacturing project's structural demands, the balance of strength versus weight, the impact on machining and fabrication processes, and the desired finish and tolerances.

Thinner plates are suitable for aerospace components where minimizing weight is critical, helping to meet stringent weight requirements while still providing necessary strength.

Thicker plates may require more advanced cutting tools and machinery for machining, while thinner plates can typically be processed using standard tools.

Industries that commonly use 6061 T651 plates include aerospace, automotive, and marine sectors, due to its strength, machinability, and corrosion resistance.

6061 T651 plates provide lightweight characteristics that enhance fuel efficiency, making them ideal for structural components and chassis in automotive applications.

Resistance to saltwater corrosion is crucial for boat construction and fittings, making 6061 T651 a preferred choice in the marine industry.

The Global Aerospace Aluminum Alloys Market anticipates a growth rate of 6.0% CAGR from 2021 to 2026, with 6061 T651 plates playing a significant role in this growth.

Thicker plates may complicate precision tasks due to the deeper machining capabilities required, which can challenge the limits of standard machining practices.

Choosing the appropriate thickness affects both the cost and weight of the final product, so balancing strength and budget constraints is essential in project planning.

The global automotive aluminum market is projected to reach $40 billion by 2027, indicating a significant shift towards using high-performance aluminum alloys like 6061 T651.

Conclusion

When you're trying to pick the right 6061 T651 aluminum plate for your project, it’s pretty important to get a good grasp of what it’s all about. This particular alloy is pretty popular because it strikes a nice balance—it's strong but lightweight, resistant to corrosion, and super versatile. That means it’s used in all sorts of industries like aviation, aerospace, and even shipbuilding. Some key things you’ll want to think about are the thickness you need, the heat treatment process, and how all these factors could affect how long the material lasts and performs in your application.

Oh, and don’t forget about budgeting. It’s a good idea to do some homework on costs and also find a trusted supplier — you want to make sure you’re getting quality stuff without blowing your budget. Here at Shanghai Miandi Metal Group Co., Ltd., we take pride in offering a wide variety of aluminum products, including those 6061 T651 plates. We’re connected to a reliable factory, so you can rest assured you'll get good quality material. Keep these things in mind, and you’ll be well on your way to making smarter choices for your manufacturing needs.

Related Posts

-

Global Manufacturing Excellence of Best 5052 Aluminum Alloy Showcasing Chinese Pride in Worldwide Exports

-

2025 Copper Price Forecast Unveiling 5 Trends Every Global Buyer Must Know

-

Ultimate Guide to Sourcing Customized 6082 T6 Aluminum Bars for Global Buyers

-

Unlocking the Potential of Aluminum Alloy Plates for Innovative Industrial Applications

-

Innovative Solutions for Choosing the Right China Aluminum Plate Manufacturers

-

Understanding Import Export Certifications for Best Al 2024-T351 with a Step by Step Guide

Blog Tags: