Ultimate Guide to Sourcing Customized 6082 T6 Aluminum Bars for Global Buyers

Table of Contents

- Key Characteristics of 6082 T6 Aluminum Bars for Custom Sourcing

- Essential Specifications and Standards for Global Buyers

- Top Suppliers and Manufacturers of Customized 6082 T6 Aluminum Bars

- Sourcing Strategies: How to Find the Best Deals on Aluminum Bars

- Quality Control Practices for Custom 6082 T6 Aluminum Bars

- Navigating Shipping and Logistics for Global Aluminum Sourcing

- Maximizing Industry Efficiency: The Impact of Customized Size 5052 H112 Aluminum Bar on Lightweight Design Trends in Aerospace and Automotive

- FAQS

- Conclusion

- Related Posts

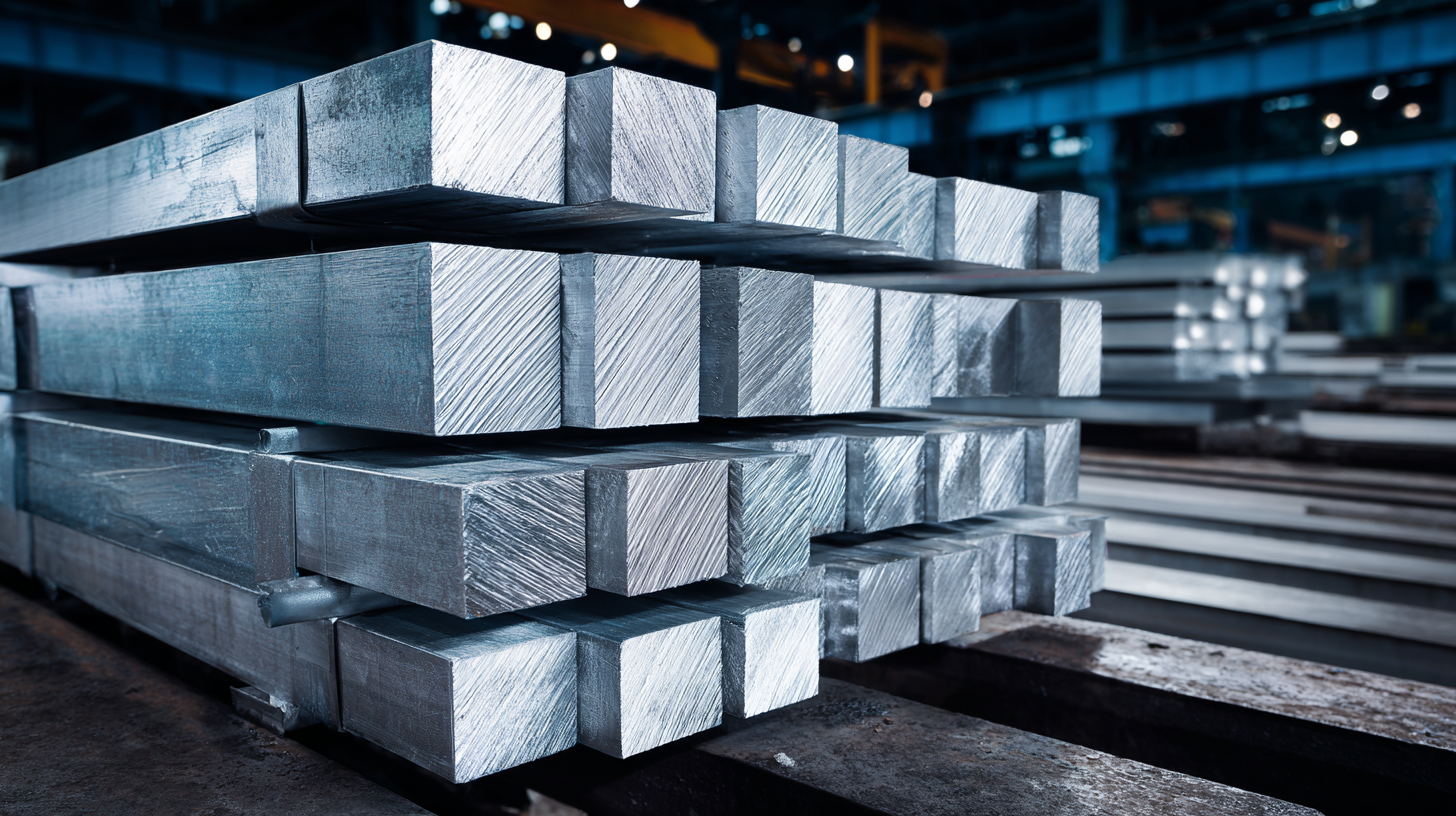

In the fiercely competitive world of sourcing aluminum, there's definitely a growing hunger for high-quality, customized aluminum products — especially for industries like aerospace and shipbuilding. If you keep an eye on industry reports, you'll see the global aluminum market is expected to hit around $189 billion by 2025. That’s mainly because of new tech and a big push toward lighter, more efficient solutions.

One of the standout products in this space is the 6082-T6 aluminum bar. It’s super popular thanks to its great mechanical properties and flexibility, making it a favorite for all kinds of structural uses. Over here at Shanghai Miandi Metal Group Co., Ltd., we’re all about providing a wide range of aluminum products, including the sought-after 6082-T6 Aluminum Bar, customized to meet what our buyers around the world need. Our catalog’s pretty extensive, covering everything from 1000 series to 8000 series aluminum — so no matter what the demand, we’ve got it covered.

Key Characteristics of 6082 T6 Aluminum Bars for Custom Sourcing

The 6082 T6 aluminum alloy is pretty well-known for having great mechanical properties, especially its high strength and resistance to corrosion. That makes it a solid choice for all sorts of industrial uses. When you process it through methods like grain refinement or plasma electrolytic oxidation (PEO), it develops a unique microstructure with finer grains, which boosts how well it performs in terms of wear and tear. Plus, recent research shows that mixing tiny bits of SiC particles into the melt during casting can actually make its mechanical properties even better. It’s pretty cool because it shows you can customize the alloy depending on what you need.

**Pro tip:** When you're hunting for 6082 T6 aluminum bars, it’s super important to think about what your project specifically needs. Things like welding and painting can really change how it performs in the real world. And don’t forget, the heat-affected zones during welding can sometimes cause issues, like weakening the material, which you definitely wanna keep an eye on if you're aiming for durability.

Going with a reputable supplier—like Shanghai Miandi Metal Group Co., Ltd.—is a smart move. They provide top-quality aluminum that meets all the strict standards, especially for high-stakes industries like aviation, aerospace, and shipbuilding. Getting a solid grasp of the quirks of 6082 T6 and how it’s processed helps you make smarter choices and find the right customized solutions for your project.

Key Characteristics of 6082 T6 Aluminum Bars

This chart illustrates the key mechanical and physical properties of 6082 T6 aluminum bars, which are essential for custom sourcing by global buyers.

Essential Specifications and Standards for Global Buyers

When you're looking to source customized 6082 T6 aluminum bars, it's super important to follow certain standards and specs. These guidelines help make sure you're getting quality material that performs well. The 6082 T6 alloy is actually pretty popular because of its great mechanical properties—it’s often the go-to choice in industries like aviation, shipbuilding, and construction where high strength and corrosion resistance are a must. According to the Aluminum Association, the 6000 series alloys, which include 6082, make up a big chunk of the aluminum market—about 24% of all aluminum used in structural stuff.

Also, don't forget to keep an eye on international standards like EN 755, which covers extruded aluminum products, or ASTM B221, which sets the rules for bars, rods, and shapes made from aluminum alloys. Sticking to these standards isn't just about being compliant—it also boosts the reliability of your final product. At Shanghai Miandi Metal Group Co., Ltd., they’re pretty good at offering a wide range of aluminum products—from 1000 all the way up to 8000 series—so whether you’re into aerospace parts or building something cool architecturally, you’re covered.

Top Suppliers and Manufacturers of Customized 6082 T6 Aluminum Bars

When you're on the hunt for customized 6082 T6 aluminum bars, finding reliable suppliers and manufacturers is absolutely key—especially if you're buying from across the globe. The 6082 T6 aluminum alloy is pretty popular because of its great strength and solid resistance to corrosion. That's why you'll see it widely used in fields like aviation, aerospace, and shipbuilding. I read recently that the demand for these aluminum products is expected to grow at around 4.5% CAGR from 2023 to 2030 — mainly thanks to the push for lighter materials in high-performance industries.

Now, one company that really stands out when it comes to aluminum supplies is Shanghai Miandi Metal Group Co., Ltd. They've got a pretty hefty selection, covering everything from 1000 to 8000 series. Whether you need plates, rods, flats, angles, tubes—you name it—they have it, and they’re pretty good at customizing things to fit specific needs. They've built a solid reputation for quality and service, making sure every product complies with international standards. Plus, they’re happy to provide certifications and test reports whenever you ask.

**Pro Tip:** When you're picking a supplier for 6082 T6 aluminum bars, don’t forget to check if they can customize the size and specifications you need. It’s always a good idea to ask for samples so you can see the quality for yourself. And, of course, double-check their production capacity and lead times—no one wants a project to get delayed because of supply hiccups!

Ultimate Guide to Sourcing Customized 6082 T6 Aluminum Bars for Global Buyers

| Supplier Location | Production Capacity (tons/year) | Customization Options | Lead Time (weeks) | Minimum Order Quantity (kg) |

|---|---|---|---|---|

| China | 5000 | Shape, Length, Surface Finish | 4 | 200 |

| Germany | 3000 | Shape, Length, Anodized Finish | 6 | 150 |

| India | 2000 | Length, Surface Treatment | 5 | 300 |

| USA | 4000 | Shape, Length, Alloy Composition | 3 | 250 |

Sourcing Strategies: How to Find the Best Deals on Aluminum Bars

When you're on the hunt for customized 6082 T6 aluminum bars, having some good strategies up your sleeve can really make all the difference in landing the best deals worldwide. First off, doing your homework is a must—spend some time browsing online platforms and industrial directories to find potential suppliers, and don't forget to check out reviews and testimonials to get a sense of their reputation. Knowing what similar folks are paying can give you a solid starting point and make negotiations smoother.

One tip I've found pretty handy is buying in bulk. If you’re planning to order a decent amount of aluminum bars, ask about discounts for bigger orders. It’s often a win-win because you pay less per piece and keep your supply steady. And honestly, chatting directly with suppliers can uncover a lot—hidden costs, special options, or tailored solutions that might just fit your needs better.

Oh, and if you get a chance, attending trade shows or industry expos can be super valuable too. Meeting manufacturers face-to-face gives you a feel for their products and helps build trust—something that’s often key for long-term relationships. Basically, mixing good research, bulk buying, and a little networking can really help you navigate the world of sourcing aluminum bars more effectively.

Quality Control Practices for Custom 6082 T6 Aluminum Bars

When you're sourcing customized 6082 T6 aluminum bars, quality control really becomes the star player in making sure the final products meet all the specs and standards that your global clients expect. Putting in place strict quality assurance steps isn't just about keeping the product top-notch — it also builds trust with your customers, which is a huge plus.

One good tip is to get clear on the quality specs right from the get-go. Work closely with your suppliers to set things like tolerances, surface finishes, and mechanical properties. Having that clarity upfront saves a lot of headaches later on and helps keep the production process smooth and efficient. Another thing that’s super helpful is doing regular audits and inspections — whether it’s a visit to the factory or bringing in third-party evaluators. That way, you’re making sure everything’s being done according to the standards you’ve agreed upon.

And hey, don’t forget about modern tech! Tools like ultrasonic testing or dye penetrant inspections are game-changers. They can scope out internal flaws or surface defects without damaging the aluminum bars, giving you a much better picture of quality. Plus, keeping a steady feedback loop with your suppliers based on what you find during these checks will definitely help improve your quality control process over time.

Navigating Shipping and Logistics for Global Aluminum Sourcing

When you're on the hunt for customized 6082 T6 aluminum bars, understanding the ins and outs of shipping and logistics can really make or break the deal—especially if you're dealing with international orders. The aluminum supply chain isn’t exactly straightforward; it usually involves a bunch of different folks, from manufacturers to freight forwarders. To get things moving smoothly, it’s super important to build solid relationships with trustworthy shipping partners who know the ropes—people familiar with global rules and regulations. That way, you’re more likely to stay on schedule and avoid surprises like unexpected costs or delays.

Choosing the right shipping method is also kinda a big deal. If you need your order fast, air freight might be the way to go. But if you’re looking to save some bucks, sea freight could be the better option—depending on how much you need and how quickly you need it. Don't forget to factor in customs duties and tariffs when you're working out the overall costs—that stuff can sneak up on you! Plus, using tech tools like tracking software can really boost your visibility during shipping, so you can plan better and keep tabs on your aluminum all the way through. Taking these steps upfront not only makes your logistics smoother but also makes the whole buying experience way less stressful and way more satisfying.

Maximizing Industry Efficiency: The Impact of Customized Size 5052 H112 Aluminum Bar on Lightweight Design Trends in Aerospace and Automotive

In the competitive landscape of aerospace and automotive industries, the demand for lightweight materials without compromising strength has become increasingly critical. The introduction of customized size 5052 H112 aluminum bars has emerged as a game-changer in maximizing industry efficiency. With diameters ranging from 4.0mm to 560mm, these aluminum bars can be tailored to meet specific design requirements, offering versatility and performance that are essential for modern engineering solutions.

The unique properties of 5052 H112 aluminum, including its excellent corrosion resistance and formability, make it an ideal choice for lightweight design trends. In aerospace applications, where every ounce counts, using precisely sized aluminum bars can significantly reduce overall weight while enhancing structural integrity. In the automotive sector, lightweight components contribute not only to fuel efficiency but also to improved handling and performance. By leveraging customized aluminum solutions, manufacturers can innovate and push the boundaries of design, optimizing every aspect of their products to meet consumer expectations and regulatory standards.

FAQS

: The 6082 T6 aluminum alloy is known for its high strength and excellent corrosion resistance. Its microstructure features a refined grain structure, especially after processes like grain refinement and plasma electrolytic oxidation, which enhances tribological performance.

The mechanical properties can be enhanced by adding micron-sized SiC particles during casting. Additionally, processes like welding and painting also significantly affect the alloy's performance.

6082 T6 aluminum bars are widely utilized in industries such as aviation, aerospace, and shipbuilding.

A trusted supplier, like Shanghai Miandi Metal Group Co., Ltd., ensures access to high-quality aluminum products that meet rigorous specifications, which is crucial for maintaining structural integrity in critical applications.

Buyers should consider the specific application requirements, the supplier's customization capabilities for dimensions and specifications, and their production capabilities and lead times for efficient project management.

It is important to establish clear quality specifications, conduct regular audits and inspections, and utilize modern technology such as non-destructive testing to ensure that products meet the required standards.

Rigorous quality assurance measures enhance product integrity and prevent misunderstandings, thereby fostering a reliable partnership with clients.

The demand for 6082 aluminum products is projected to grow at a CAGR of 4.5% from 2023 to 2030, driven by advancements in lightweight materials for high-performance applications.

Buyers should ask for samples to evaluate product quality and request certifications and material test reports to confirm adherence to international standards.

Conclusion

In our 'Ultimate Guide to Sourcing Customized 6082 T6 Aluminum Bars for Global Buyers,' we take a closer look at what makes these aluminum bars so popular for all kinds of uses. If you're trying to figure out what to look for, don’t worry — we cover the key specs and industry standards that are essential for making sure you get quality products that meet your needs. Plus, we shine a spotlight on some top suppliers and manufacturers who specialize in customizing 6082 T6 aluminum bars, giving you a clear road map on how to source them effectively, snag the best deals, and keep quality in check.

Of course, shipping and logistics can get pretty complex when you’re sourcing aluminum from around the world. Luckily, Shanghai Miandi Metal Group Co., Ltd. offers a wide range of aluminum products, including customized options. So whether you're working in aerospace, shipbuilding, or other fields, you'll find helpful info here to make smarter sourcing choices and streamline your supply chain. Picking the right strategy for sourcing 6082 T6 aluminum bars can really make a big difference in the success of your projects.

Related Posts

-

Global Manufacturing Excellence of Best 5052 Aluminum Alloy Showcasing Chinese Pride in Worldwide Exports

-

Navigating Import and Export Certifications for Best 6061 Aluminum Alloy Products in Global Markets

-

Discover Superior Manufacturing with Chinas Best T351 Aluminum Solutions

-

Understanding Import Export Certifications for Best Al 2024-T351 with a Step by Step Guide

-

Global Market Analysis 2025 for Best Weldable Aluminum Alloy and How to Choose the Right Supplier

-

Top Strategies for Sourcing Affordable 6061 T6 Aluminum in the Global Market

Blog Tags: