1. Introduction to 1060 Aluminum Alloy

1060 aluminum sheet is a high-purity aluminum alloy widely recognized for its excellent corrosion resistance, thermal conductivity, and formability. Comprising approximately 99.6% aluminum, this alloy is part of the 1000 series, which is characterized by minimal impurities and exceptional workability. Its chemical composition adheres to international standards such as ASTM B209 and GB/T 3880.1, ensuring consistency and reliability across global markets.

2. Chemical Composition and Microstructure

The primary alloying elements in 1060 aluminum are limited to trace amounts of iron (Fe ≤ 0.35%) and silicon (Si ≤ 0.25%), with other impurities strictly controlled below 0.05%. This low intermetallic content contributes to its homogeneous microstructure, which remains non-heat-treatable but highly amenable to cold working. The absence of significant alloying elements like copper or magnesium ensures minimal galvanic corrosion risks, making it ideal for environments with chemical exposure.

3. Mechanical and Physical Properties

1060 aluminum sheet exhibits a tensile strength of 90-120 MPa and a yield strength of 45-60 MPa in the O-temper (annealed) condition. Its elongation rate (15-25%) underscores its superior ductility, enabling deep drawing and bending without cracking. Thermally, it boasts a thermal conductivity of 237 W/m·K, outperforming most structural alloys. Additionally, its electrical conductivity (61% IACS) makes it a preferred choice for electrical applications.

4. Surface Treatment and Formability

To enhance performance, 1060 aluminum sheets can undergo annealing, rolling, or annealing treatments to achieve desired hardness levels (H14, H18, H24). Surface finishes such as mill finish, brushed, or anodized coatings further improve corrosion resistance and aesthetic appeal. The alloy’s low yield strength allows seamless integration into complex forming processes, including stamping, extrusion, and roll forming, without compromising dimensional stability.

5. Key Applications Across Industries

A. Electronics and Electrical Engineering

The high thermal and electrical conductivity of 1060 aluminum sheets makes them indispensable in heat sinks, electrical enclosures, and busbar systems. Their lightweight yet durable nature ensures efficient heat dissipation in power electronics and LED lighting systems.

B. Architectural and Construction

In the construction sector, 1060 sheets are utilized for curtain walls, roofing panels, and interior partitions. Their UV resistance and non-magnetic properties align with modern architectural demands for energy-efficient and aesthetically pleasing structures.

C. Transportation and Automotive

The alloy’s low density (2.7 g/cm³) and corrosion resistance make it suitable for automotive components, including battery casings, fuel tanks, and lightweight structural parts. In rail transit, it is employed for interior panels and door systems, reducing vehicle weight while maintaining safety standards.

D. Food Processing and Packaging

1060 aluminum’s non-toxic surface and hygienic properties comply with FDA and ISO 22000 certifications, making it a staple in food-grade containers, beverage cans, and pharmaceutical packaging. Its non-reactive surface prevents contamination in sensitive environments.

E. General Manufacturing

From chemical processing tanks to marine equipment, 1060 aluminum sheets offer saltwater corrosion resistance and dimensional stability, even in harsh industrial conditions.

6. Advantages Over Competing Alloys

Compared to 6061 or 3003 aluminum, 1060 offers higher purity, lower cost, and superior formability, albeit with slightly reduced strength. Its ease of welding and machining further reduce production costs, making it a cost-effective alternative for non-structural applications.

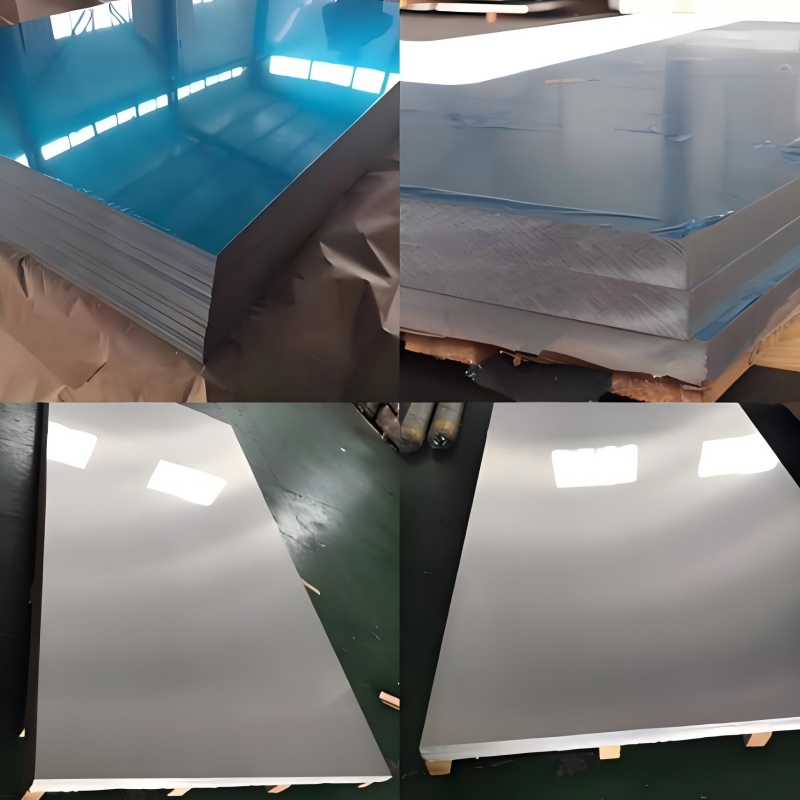

7. Quality Assurance and Customization

Our 1060 aluminum sheets are manufactured under ISO 9001:2015 and ISO 14001:2015 certifications, ensuring compliance with ASTM, EN, and JIS standards. We offer customization in thickness (0.2-200 mm), width (50-2000 mm), and temper (O, H112, H14) to meet diverse client requirements.

8. Why Choose 1060 Aluminum Sheets?

For industries prioritizing cost-effectiveness, corrosion resistance, and thermal performance, 1060 aluminum sheets represent an optimal solution. Whether for high-tech electronics, sustainable construction, or food-safe packaging, our products combine technical precision with unmatched versatility.

Contact Us Today

To discuss your project requirements or request a sample, contact our team of aluminum specialists. With over 10 years of experience in aluminum plate, rod, and machining solutions, we deliver tailored materials that exceed expectations.

Post time: Nov-20-2025