For engineers, procurement specialists, and manufacturers in aerospace, automotive, and precision engineering, 2024 aluminum plates stand out as a high-strength, heat-treatable alloy tailored for load-bearing and structural applications. Unlike general-purpose alloys such as 6061, known for versatility but limited in strength, 2024 belongs to the 2000 series aluminum alloys (copper-based), a category celebrated for its exceptional mechanical performance in demanding environments. Below is a comprehensive breakdown of 2024 aluminum plates’ chemical composition, key properties, and application ranges, designed to help you select the optimal material for high-stress, precision-driven projects while aligning with global industry standards.

Chemical Composition: The Core of 2024’s Structural Strength

The performance of 2024 aluminum plates is rooted in its precisely calibrated chemical makeup, which adheres to strict industry specifications including ASTM B209 (Standard Specification for Aluminum and Aluminum Alloy Plates) and AMS 4037 (Aerospace Material Specification for 2024 Aluminum Alloy Plate, Sheet, and Strip). As a copper-dominant alloy, 2024 relies on three primary alloying elements to achieve its signature strength, with trace elements carefully controlled to refine microstructure and stability.

- Copper (Cu): 3.8%~4.9%. The primary strengthening agent. Copper forms hard, discrete intermetallic phases (e.g., Al₂CuMg, AlCu₂Mn) during heat treatment, which precipitate within the aluminum matrix to resist plastic deformation. This high copper content is the single most critical factor behind 2024’s industry-leading tensile and yield strength, outperforming many other aluminum alloys in structural applications.

- Magnesium (Mg): 1.2%~1.8%. Works synergistically with copper to enhance hardening efficiency. Magnesium increases the density and distribution of precipitated phases, amplifying both strength and fatigue resistance. Without magnesium, copper alone would not deliver the balanced performance that makes 2024 ideal for cyclic-load applications (e.g., aircraft wings).

- Manganese (Mn): 0.3%~0.9%. A key grain refiner. Manganese limits the growth of aluminum grains during casting and heat treatment, creating a finer, more uniform microstructure. This refinement improves both mechanical consistency across the plate and resistance to stress corrosion cracking (SCC), a critical advantage for components exposed to fluctuating loads.

- Trace Elements & Impurities. Silicon (Si ≤ 0.50%), iron (Fe ≤ 0.50%), zinc (Zn ≤ 0.30%), chromium (Cr ≤ 0.10%), titanium (Ti ≤ 0.15%), and other impurities (total ≤ 0.15%) are tightly regulated. Iron and silicon, if present in excess, can form brittle intermetallic inclusions (e.g., AlFeSi) that weaken the alloy, while titanium further refines grain structure for better formability.

Deviations from these compositional ranges can drastically compromise performance: even a 0.5% overshoot in copper content may increase brittleness, while insufficient magnesium can reduce strength by up to 20%. For this reason, all 2024 aluminum plates from reputable suppliers include a Material Test Certificate (MTC) verifying compliance with ASTM/AMS standards.

Key Mechanical & Physical Properties

2024 aluminum plates are valued for their unique balance of strength, fatigue resistance, and formability, properties optimized through heat treatment (most commonly the T3, T4, and T6 tempers, each tailored to specific application needs). Below are the critical performance metrics that make 2024 a top choice for structural applications:

1. Mechanical Strength & Fatigue Resistance

- Tensile Strength: Ranges from 427MPa (62,000psi) in the T4 temper to 483MPa (70,000psi) in the T6 temper. This means 2024 can withstand up to 48 kilograms of force per square millimeter before fracture, surpassing 6061-T6 (310MPa) by 56% and making it ideal for load-bearing components.

- Yield Strength: Varies from 276MPa (40,000psi) (T4) to 414MPa (60,000psi) (T6). Yield strength measures the force at which permanent deformation begins; for safety-critical parts (e.g., aircraft fuselage frames), this metric is non-negotiable to prevent catastrophic failure.

- Elongation at Break: 12%~18% (in 50 mm gauge length), depending on temper. While 2024 is far stronger than 6061, it retains sufficient ductility for forming processes like bending, rolling, and stamping, critical for manufacturing complex shapes (e.g., automotive suspension brackets).

- Fatigue Strength: 103MPa (15,000psi) at 10⁷ cycles (T3 temper). This exceptional fatigue resistance allows 2024 to endure repeated stress (e.g., aircraft takeoffs and landings) without cracking, a key advantage over less durable alloys.

2. Machinability & Formability

2024 aluminum plates excel in precision machining, particularly in the T3 and T6 tempers. Its fine-grained microstructure minimizes “chip welding” (a common issue with softer alloys) and reduces tool wear by up to 25% compared to 2017 aluminum. It performs exceptionally well in:

- CNC milling (for complex structural components like engine mounts)

- Stamping (for thin-gauge parts like aircraft interior panels)

- Drilling (for high-tolerance holes in automotive chassis parts)

In the T4 temper (solution-treated and naturally aged), 2024 offers enhanced formability, making it suitable for deep drawing and stretch forming processes that require the alloy to be bend without cracking.

3. Corrosion Resistance

2024 aluminum plates exhibit moderate atmospheric corrosion resistance (e.g., to humidity and mild industrial pollutants) but require surface treatments for use in harsh environments (e.g., marine, salt-spray, or chemical exposure). Common protective coatings include:

- Anodizing (creates a hard, porous oxide layer for enhanced durability)

- Chromate conversion coating (improves paint adhesion and corrosion resistance)

- Powder coating (adds a decorative, scratch-resistant finish for consumer-facing parts)

Notably, 2024 is less prone to stress corrosion cracking (SCC) than other high-copper alloys (e.g., 2014) when properly heat-treated, making it a safer choice for outdoor or cyclic-load applications.

4. Physical Properties

- Density: 2.78g/cm³, 31% lighter than steel (7.85g/cm³) and 9% lighter than brass, a critical advantage for weight-sensitive projects (e.g., electric vehicle bodies, drone frames).

- Thermal Conductivity: 121W/(m·K), lower than pure aluminum (237W/(m·K)) but sufficient for applications that requiring moderate heat dissipation (e.g., industrial heat exchangers).

- Melting Range: 502°C~638°C (936°F~1180°F) compatible with standard aluminum heat-treatment processes and ensuring stability in high-temperature environments (e.g., under-hood automotive parts).

Application scope: 2024 aluminum plate advantages

2024’s unique combination of strength, fatigue resistance, and formability makes it indispensable across industries that demand reliability in structural and load-bearing components. Below are its most common, high-value use cases:

1. Aerospace & Defense (Primary Market)

The aerospace industry is 2024’s largest consumer, as it meets the strict “aerospace-grade” requirements for strength, weight, and durability. Applications include:

- Aircraft structural components: Fuselage skins, wing ribs, and bulkheads (where strength-to-weight ratio directly impacts fuel efficiency).

- Aerospace interiors: Seat frames, cargo compartment panels, and overhead bin supports (where formability and light weight are key).

- Defense equipment: Armored vehicle plates, missile casings, and helicopter rotor components (where resistance to impact and cyclic stress is critical).

2. Automotive (High-Performance & EV)

For automotive manufacturers, 2024 aluminum plates enable lightweighting without sacrificing safety, a top priority for electric vehicles (EVs) and high-performance cars. Key applications:

- EV components: Battery pack enclosures, motor housings, and chassis rails (reducing vehicle weight to extend range).

- High-performance vehicles: Suspension arms, brake calipers, and drive shafts (improving handling by lowering unsprung weight).

- Racing vehicles: Roll cages and body panels (where strength and light weight enhance speed and maneuverability).

3. Industrial Machinery & Tooling

In industrial settings, 2024 is used for parts that endure repeated stress or require precision:

- Machine tool components: CNC machine bases, tool holders, and press plates (where stability prevents vibration during machining).

- Heavy equipment: Hydraulic cylinder barrels, crane boom sections, and conveyor system frames (where strength resists bending under load).

- Mold & die making: Prototyping molds and low-volume production dies (where formability allows for complex cavity shapes).

4. Sports & Recreational Equipment

Even consumer products benefit from 2024’s strength and light weight:

- Bicycle parts: Frame tubes and fork blades (for durability during off-road riding).

- Boating equipment: Small boat hulls and sailboat mast components (when paired with anti-corrosion coatings).

- Fitness gear: Weightlifting platforms and gym equipment frames (where strength supports heavy loads).

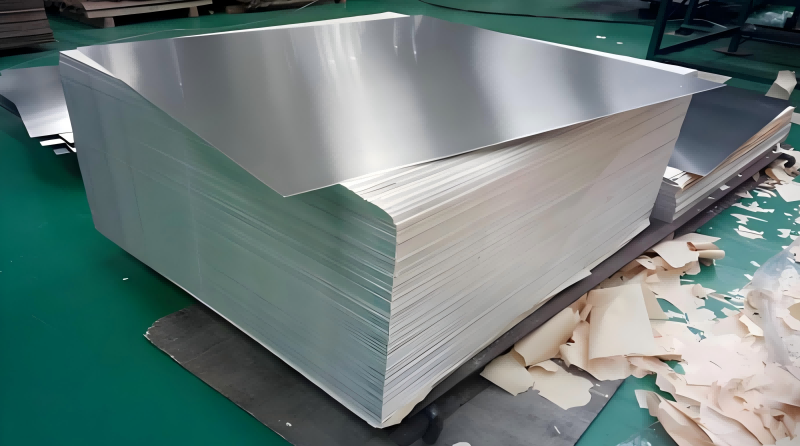

Partner With Us for Premium 2024 Aluminum Plates

We specialize in manufacturing 2024 aluminum plates that meet or exceed global standards (ASTM B209, AMS 4037, DIN 1725). Our plates are available in:

- Thicknesses: 0.8 mm to 200 mm (custom thicknesses available for large-volume orders).

- Tempers: T3 (solution-treated, cold-worked, naturally aged), T4 (solution-treated, naturally aged), T6 (solution-treated, artificially aged).

- Surface Finishes: Mill finish (for machining), anodized (clear/colored), chromate-coated (aerospace-grade), and powder-coated (custom colors).

Every batch of 2024 aluminum sheets we produce comes with a detailed Material Traceability Certificate (MTC), ensuring complete traceability for your quality control processes. Whether you need small-batch samples for prototype development or large-volume orders for mass production, we offer competitive pricing, flexible delivery cycles, and technical support to help you optimize material selection.

Contact us now to request samples, inquire about custom specifications, or obtain a no-obligation quote. Our aluminum alloy expertise empowers you to create products with enhanced strength, reduced weight, and improved reliability, while ensuring global compliance and consistent quality.

Post time: Nov-03-2025