In the vast landscape of aluminum alloys, 3003 aluminum sheet stands as a quintessential workhorse. Renowned for its excellent combination of strength, formability, and corrosion resistance, it fills a critical niche between commercially pure aluminum and the higher-strength alloys. For engineers, fabricators, and designers, understanding the specific attributes of 3003 aluminum is key to selecting the optimal material for a wide array of industrial projects. This article provides a detailed exploration of 3003 aluminum sheet, dissecting its properties, performance metrics, and multifaceted applications.

Chemical Composition and Metallurgical Foundation

3003 aluminum is classified as a non-heat-treatable alloy. Its enhanced properties are achieved through strain hardening, also known as work hardening. The alloy’s core composition is aluminum-manganese, with manganese (Mn) serving as the primary alloying element, typically ranging from 1.0% to 1.5%. This addition of manganese significantly increases the strength of the base aluminum—approximately 20% stronger than 1100 series aluminum—without substantially compromising its ductility. Small amounts of copper (Cu) are also present to further contribute to strength.

This specific metallurgical recipe is the foundation for all the beneficial characteristics that 3003 aluminum sheet exhibits.

Key Characteristics and Mechanical Properties

The popularity of 3003 aluminum sheet is directly attributable to its well-balanced portfolio of properties.

· Excellent Corrosion Resistance: 3003 aluminum possesses very good resistance to atmospheric corrosion. It forms a protective oxide layer that, when damaged, self-repairs in the presence of oxygen. This makes it highly suitable for applications exposed to the elements, though it is not recommended for highly chemical or marine environments without appropriate protective coatings.

· Superb Formability and Workability: This is one of its most valued traits. 3003 aluminum sheet can be readily bent, stamped, drawn, and roll-formed into complex shapes without cracking. Its high ductility in the annealed (O-temper) state allows for deep drawing operations, making it a favorite for spun and drawn containers.

· Good Strength: With a tensile strength that surpasses the 1000-series alloys, 3003 provides a practical strength-to-weight ratio. It is commonly supplied in various tempers, such as H14 (work hardened and partially annealed) or H18 (full hard), to offer varying levels of strength and formability for different fabrication needs.

· Superior Weldability: 3003 aluminum sheet can be easily welded using all common techniques, including Gas Tungsten Arc Welding (GTAW/TIG) and Gas Metal Arc Welding (GMAW/MIG). This facilitates the creation of robust, integrated structures.

· High Thermal Conductivity: Like most aluminum alloys, 3003 is an excellent conductor of heat. This property is crucial for heat exchangers and cooking utensils, where efficient thermal transfer is paramount.

Industrial Applications: Where 3003 Aluminum Sheet Excels

The versatile properties of 3003 aluminum sheet make it indispensable across numerous sectors. Its reliability and cost-effectiveness ensure its continued dominance in both traditional and innovative applications.

1. Transportation Industry: In the automotive and aerospace sectors, weight reduction is a perpetual goal. 3003 sheet is extensively used for non-structural components, including truck and trailer body panels, radiator shrouds, and interior trim. Its formability allows for the creation of complex aerodynamic parts, while its strength ensures durability.

2. Heat Exchangers and HVAC Systems: The alloy’s excellent thermal conductivity and corrosion resistance make it the material of choice for charge air coolers, evaporators, and condenser fins. In residential and commercial HVAC systems, 3003 sheet is fabricated into heat sink assemblies and ventilation ducts.

3. Food and Chemical Processing Equipment: 3003 is approved for food contact by relevant regulatory bodies. Its non-toxic, non-absorbent surface and resistance to organic acids make it ideal for storage tanks, silos, shipping containers, and processing vats. It is also the primary material for many types of cookware, baking sheets, and residential gutters and downspouts.

4. General Sheet Metal Work and Fabrication: For general fabrication shops, 3003 aluminum sheet is a staple. It is used to create toolboxes, machine guards, decorative panels, and signage. Its ease of welding and finishing allows for high-quality, aesthetically pleasing end products.

5. Building and Construction: While not as strong as 5000 or 6000 series alloys for structural applications, 3003 is widely used for architectural facades, ceiling panels, and roofing sheets where its formability and surface finish are advantageous.

Why Source Your 3003 Aluminum Sheet from Us?

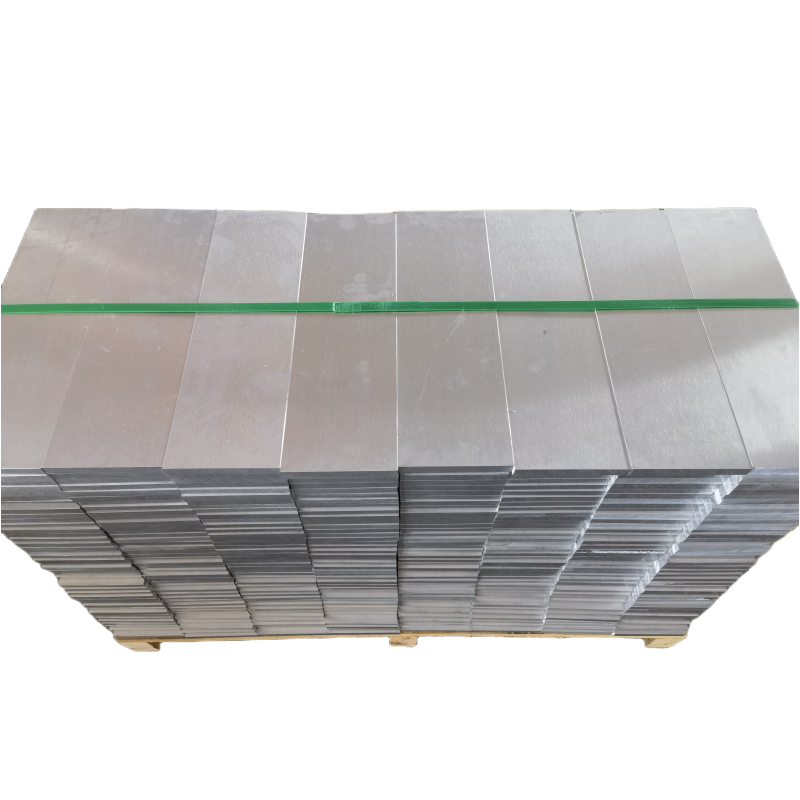

As a specialist in aluminum plate, rod, tube, and precision machining, we provide more than just material. We offer a partnership. Our 3003 aluminum sheet is sourced from top-tier mills, guaranteeing consistent chemistry, precise temper, and superior surface quality. We stock a comprehensive range of sizes and tempers to meet your specific project requirements. Our in-house machining capabilities mean we can also supply pre-cut blanks, custom shapes, or fully machined components, saving you time and reducing waste.

For your next project that demands a perfect balance of form, function, and reliability, specify 3003 aluminum sheet. Request a quote today or contact our technical sales team to discuss how we can support your supply chain and manufacturing goals.

Post time: Oct-13-2025