In the realm of non-ferrous metals, 5754 aluminum plate stands out as a versatile and high-performance material belonging to the Al-Mg (aluminum-magnesium) alloy series. Renowned for its balanced blend of strength, corrosion resistance, and formability, it has become a staple in industries ranging from automotive manufacturing to marine engineering and construction. As a trusted supplier of aluminum products and machining services, we aim to provide a comprehensive overview of 5754 aluminum plate—breaking down its chemical composition, mechanical properties, key characteristics, and practical applications—to help you make informed decisions for your projects.

1. Chemical Composition of 5754 Aluminum Plate

The superior performance of 5754 aluminum plate is directly tied to its precisely controlled chemical makeup, with magnesium (Mg) serving as the primary alloying element. Below is the detailed composition per international standards (e.g., ASTM B209, EN 573-3):

- Magnesium (Mg): 3.1% – 3.9%

As the core alloying element, magnesium significantly enhances the plate’s tensile strength and yield strength while maintaining excellent ductility. It also plays a critical role in improving corrosion resistance, particularly against marine and industrial environments, by promoting the formation of a stable passive oxide film on the surface.

- Manganese (Mn): Maximum 0.50%

Manganese acts as a secondary strengthener, refining the alloy’s grain structure to boost workability and toughness. It also mitigates the risk of “hot cracking” during welding, a common challenge in high-magnesium aluminum alloys.

- Chromium (Cr): Maximum 0.30%

Chromium further refines grain size, enhancing the plate’s resistance to stress corrosion cracking (SCC)—a key advantage for applications exposed to cyclic loads or harsh chemicals.

- Trace Elements (Maximum Limits):

- Iron (Fe): 0.40%

- Silicon (Si): 0.40%

- Copper (Cu): 0.10%

- Zinc (Zn): 0.25%

- Titanium (Ti): 0.15%

These trace elements are strictly controlled to avoid compromising the alloy’s core properties, such as ductility and weldability.

- Aluminum (Al): Remainder

Pure aluminum forms the base matrix, providing the material’s inherent light weight (density: 2.68 g/cm³) and thermal/electrical conductivity.

2. Mechanical Properties of 5754 Aluminum Plate

The mechanical performance of 5754 aluminum plate varies slightly depending on its temper (heat treatment or work-hardening state), making it adaptable to diverse application requirements. The most common tempers for 5754 plate are O (annealed), H111 (strain-hardened to a moderate strength), and H32 (strain-hardened and stabilized). Below are the typical mechanical properties (per ASTM B209):

Temper Tensile Strength (Minimum) Yield Strength (Minimum) Elongation (in 50mm, Minimum)

O (Annealed) 220 MPa (31.9 ksi) 95 MPa (13.8 ksi) 25%

H111 230 MPa (33.4 ksi) 110 MPa (15.9 ksi) 20%

H32 (Work-Hardened & Stabilized) 260 MPa (37.7 ksi) 180 MPa (26.1 ksi) 15%

- Tensile Strength: The maximum stress the plate can withstand before breaking. The H32 temper, with its higher tensile strength, is ideal for load-bearing components.

- Yield Strength: The stress at which the material begins to deform permanently. H32’s elevated yield strength ensures dimensional stability in structural applications.

- Elongation: A measure of ductility. The O temper’s high elongation (25%) makes it perfect for complex forming processes like deep drawing or bending.

Additionally, 5754 aluminum plate exhibits good fatigue resistance, with an endurance limit of approximately 100 MPa (14.5 ksi) under cyclic loading—critical for parts like automotive suspension components or marine fasteners.

3. Key Characteristics of 5754 Aluminum Plate

What sets 5754 aluminum plate apart from other alloys is its unique combination of properties, making it a “jack-of-all-trades” material:

- Exceptional Corrosion Resistance

The Al-Mg matrix forms a dense, self-healing oxide layer that resists attack from saltwater, industrial chemicals, and atmospheric moisture. This makes it far more corrosion-resistant than pure aluminum or Al-Cu alloys, making it a top choice for marine and offshore applications.

- Superior Formability

Even in its stronger tempers (e.g., H32), 5754 plate retains excellent ductility. It can be easily bent, rolled, stamped, or deep-drawn into complex shapes without cracking—ideal for manufacturing curved automotive panels or custom architectural components.

- Excellent Weldability

5754 plate is compatible with all common welding methods, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and resistance welding. Welded joints maintain high strength and corrosion resistance, with minimal post-weld heat treatment required.

- Moderate Strength-to-Weight Ratio

While not as strong as high-strength alloys like 6061 or 7075, 5754 offers a better strength-to-weight ratio than pure aluminum. This balance makes it suitable for applications where weight reduction is critical (e.g., automotive bodies) without sacrificing structural integrity.

- Good Thermal & Electrical Conductivity

With a thermal conductivity of ~120 W/(m·K) (O temper), 5754 plate efficiently dissipates heat—making it useful for heat sinks, electronic enclosures, and HVAC components. Its electrical conductivity (约30% IACS) also suits low-voltage electrical applications.

4. Industrial Applications of 5754 Aluminum Plate

Thanks to its versatile properties, 5754 aluminum plate is widely used across multiple industries. Below are its most common applications。

4.1 Automotive Industry

5754 plate is a preferred material for lightweight automotive components, including:

- Body panels (doors, fenders, hoods) due to its formability and corrosion resistance.

- Chassis parts (cross members, brackets) for its strength-to-weight ratio.

- Fuel tanks and heat shields, leveraging its resistance to fuel and high temperatures.

4.2 Marine & Offshore Engineering

Its resistance to saltwater corrosion makes it ideal for:

- Boat hulls, decks, and superstructures.

- Offshore platform components (handrails, gratings, pipe clamps).

- Marine fasteners and fittings (when machined to precision).

4.3 Construction & Architecture

In building projects, 5754 plate is used for:

- Architectural cladding and facades (thanks to its aesthetic appeal and weather resistance).

- Roofing panels and gutter systems (corrosion-resistant and lightweight).

- Structural supports for modular buildings (easily cut and machined to size).

5. Why Choose Our 5754 Aluminum Plate?

As a leading supplier of aluminum products and machining services, we ensure our 5754 aluminum plate meets the highest standards:

- Premium Raw Materials: Sourced from certified mills to guarantee consistent composition and performance.

- Strict Quality Control: Each plate undergoes testing (tensile, corrosion, dimensional) to comply with ASTM, EN, and ISO standards.

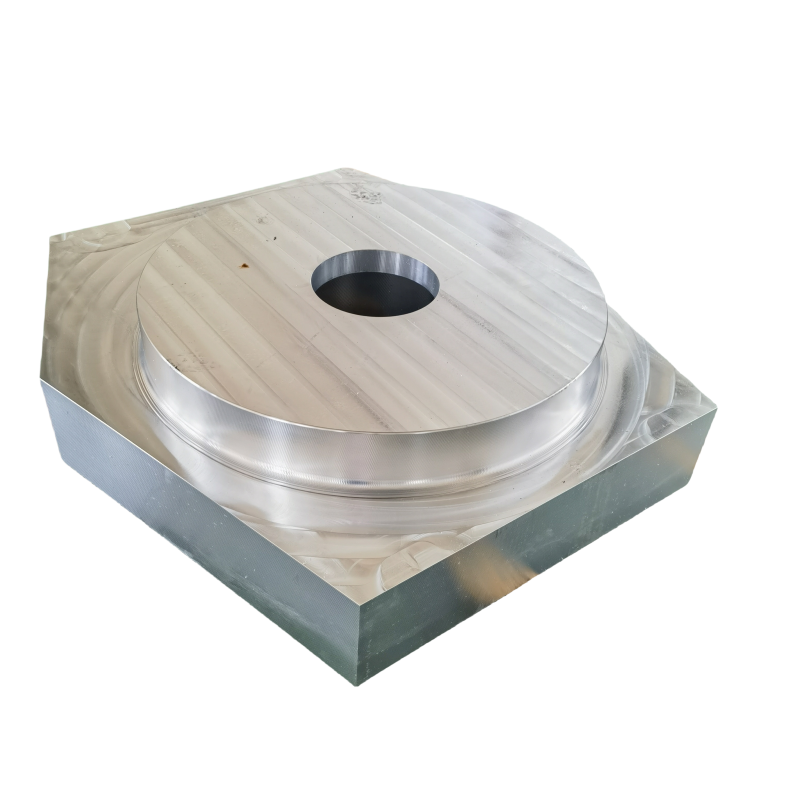

- Customization: We offer cut-to-size, CNC machining, and surface finishing (anodizing, painting) to match your exact project needs.

- Reliable Delivery: Our streamlined supply chain ensures on-time delivery for both small-batch prototypes and large-scale production.

5754 aluminum plate is a versatile, high-performance material that excels in applications requiring a balance of strength, corrosion resistance, and formability. Its well-engineered composition, adaptable mechanical properties, and broad industrial applicability make it a top choice for automotive, marine, construction, and machining projects.

Whether you need raw 5754 plates or precision-machined components, our team is equipped to deliver solutions that meet your specifications. Contact us today to request a quote, technical datasheet, or sample—and experience the reliability of premium 5754 aluminum plate for your next project.

Post time: Sep-22-2025