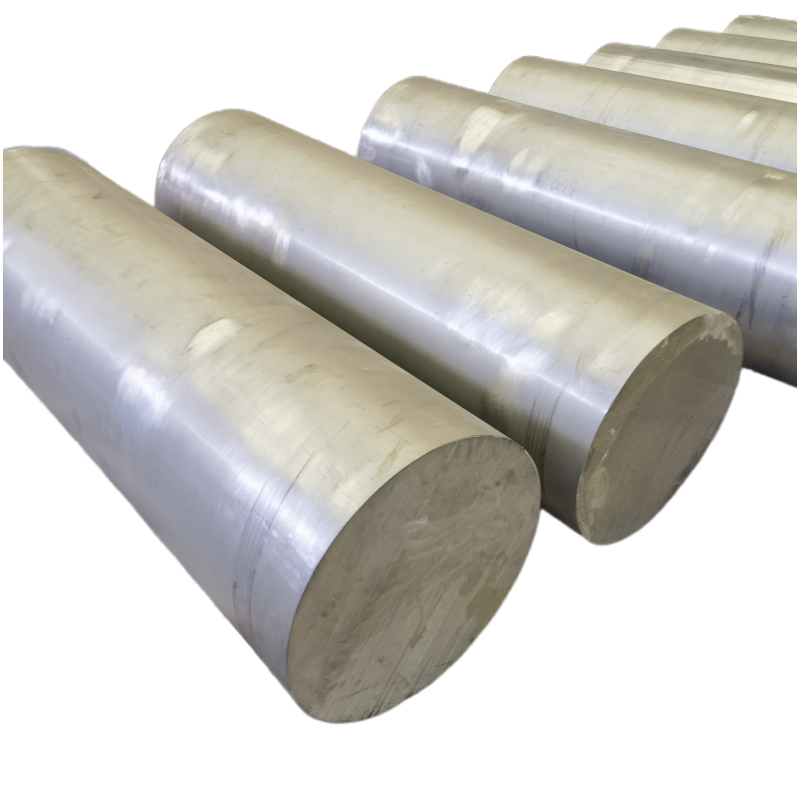

As a precipitation-hardenable Al-Mg-Si alloy, 6061 aluminum is renowned for its exceptional balance of strength, corrosion resistance, and machinability. Commonly processed into bars, plates and tubes, this alloy finds extensive use in industries demanding robust yet lightweight materials. The T6 and T651 temper conditions further optimize its properties for specific applications, making it the cornerstone in modern manufacturing.

Mechanical and Physical Properties of 6061 T6 & T651 Aluminum Bars

T6 Temper (Solution Heat Treated + Artificial Aging)

- Tensile Strength: Up to 310 MPa (45 ksi), with yield strength reaching 276 MPa (40 ksi).

- Elongation: 12-17%, ensuring good ductility for forming operations.

- Density: 2.7 g/cm³, contributing to its lightweight advantage.

- Corrosion Resistance: Excellent resistance to atmospheric corrosion, ideal for outdoor applications.

- Thermal Conductivity: 180 W/m·K, facilitating heat dissipation in thermal management systems.

T651 Temper (T6 with Stress Relief)

- Distinguished by controlled stress relief through stretching, T651 bars exhibit minimized distortion during machining.

- Similar mechanical properties to T6 but with improved dimensional stability, making them suitable for precision components.

- Reduced internal stresses enhance performance in critical load-bearing applications.

Key applications of 6061 aluminum bars

1. Aerospace & Aviation:

- Aircraft structural components (fuselage frames, wing ribs) due to high strength-to-weight ratio.

- Landing gear parts and brackets requiring corrosion resistance in harsh environments.

2. Automotive & Transportation:

- Chassis components, suspension arms, and engine parts to reduce vehicle weight and improve fuel efficiency.

- Motorcycle frames and bicycle components for durability and impact resistance.

3. Industrial & Machinery:

- Machine tool fixtures, gears, and shafts in CNC machining applications.

- Structural supports in robotics and automation systems.

4. Marine & Outdoor Equipment:

- Boat hulls, deck fittings, and marine hardware due to resistance to saltwater corrosion.

- Outdoor signage and architectural elements requiring weather durability.

5. Consumer & Sports Equipment:

- Bicycle frames, golf club heads, and kayak components for lightweight performance.

- High-end consumer electronics casings for aesthetic and structural integrity.

Custom Machining Capabilities for 6061 Aluminum Bars

1. Precision Cutting & Shaping:

- CNC turning, milling, and drilling to tight tolerances (±0.01 mm).

- Custom diameters (from 6 mm to 300 mm) and lengths up to 6 meters, tailored to project specifications.

2. Surface Treatment Options:

- Anodizing (Type II/III) for enhanced corrosion resistance and aesthetic finishes.

- Powder coating for durable, color-customizable surfaces.

- Polishing and bead blasting for specific texture requirements.

3. Value-Added Services:

- Engineering support for design optimization, including DFM (Design for Manufacturing) consultations.

- Prototyping services for rapid product development.

- Bulk production with strict quality control (ISO 9001 certified), ensuring material traceability and mechanical property compliance.

6061 T6 and T651 aluminum bars embody the versatility demanded by modern manufacturing, combining mechanical robustness with processability. Whether for aerospace precision or industrial durability, their properties make them indispensable. With custom machining capabilities spanning from material temper selection to post-processing finishes, these alloys offer scalable solutions for diverse applications. For tailored 6061 aluminum bar solutions — from raw material supply to fully machined components—partner with our expertise in metal fabrication and engineering.

Post time: Jul-03-2025