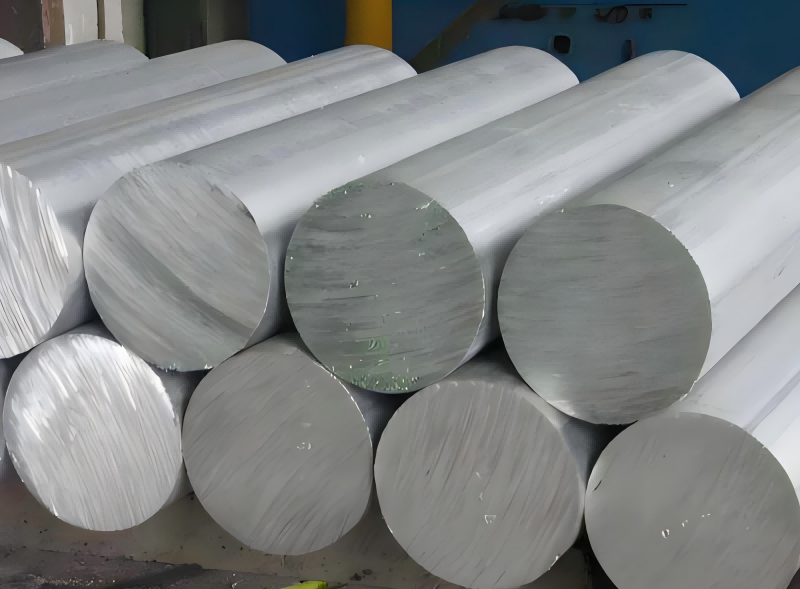

In the hierarchy of engineering materials, where the relentless pursuit of maximum strength to weight ratio meets the reality of harsh operating environments, one aluminum alloy stands above the rest: 7075. In its peak aged T6 and stress relieved T6511 tempers, 7075 aluminum bar represents the gold standard for high performance applications. This technical dossier provides a comprehensive analysis of 7075-T6/T6511 aluminum round bar, detailing its sophisticated metallurgy, exceptional properties, and the mission critical industries it serves.

1. Precision Engineered Chemical Composition: The Foundation of Strength

The extraordinary strength of 7075 aluminum is not accidental; it is the direct result of a meticulously formulated chemical composition centered on a zinc-magnesium-copper system. This alloy belongs to the 7xxx series (Al-Zn-Mg-Cu), renowned for achieving the highest strengths of all aluminum alloys via precipitation hardening.

The standard composition is critically balanced as follows:

· Aluminum (Al): Balance

· Zinc (Zn): 5.1%~6.1% (Primary strengthening element)

· Magnesium (Mg): 2.1%~2.9% (Co-strengthening element, forms MgZn₂ precipitates)

· Copper (Cu): 1.2%~2.0% (Enhances strength and improves stress-corrosion cracking resistance)

· Chromium (Cr): 0.18%~0.28% (Grain refiner, controls recrystallization and improves toughness)

· Iron (Fe): ≤ 0.50%

· Silicon (Si): ≤ 0.40%

· Manganese (Mn): ≤ 0.30%

· Titanium (Ti): ≤ 0.20%

· Other Elements (Each): ≤ 0.05%

Metallurgical Insight: The high concentrations of Zinc and Magnesium enable the formation of a high density of fine, metastable η’ (MgZn₂) precipitates during the artificial aging process (T6 temper). Copper enters solid solution and also forms fine precipitates, further amplifying strength and modifying the precipitate structure to enhance resistance to stress corrosion cracking (SCC). This complex synergy creates formidable barriers to dislocation movement, yielding its unparalleled strength.

2. Exceptional Mechanical and Physical Properties

The T6 temper involves solution heat treatment, quenching, and artificial aging to achieve peak strength. The T6511 temper goes a critical step further: after solution heat treatment, the bar is stress-relieved by stretching (typically 1%~3% permanent set) before artificial aging, and is supplied as a drawn bar.

· T6 Temper: Delivers the absolute maximum strength. However, the quenching process can induce significant internal (residual) stresses.

· T6511 Temper: The stretching process plastically deforms the bar, dramatically reducing these residual stresses. This is the critical differentiator for machining. A T6511 bar exhibits vastly superior dimensional stability during heavy machining, minimizing warping and distortion, and allowing for the achievement of tight tolerances.

Mechanical Properties (Typical Minimum Values for 7075-T6/T6511)

· Tensile Strength: 83 ksi (572 MPa)

· Yield Strength (0.2% Offset): 73 ksi (503 MPa)

· Elongation: 8%~11% in 2 inches

· Shear Strength: 48 ksi (331 MPa)

· Hardness (Brinell): 150 HB

· Fatigue Strength: 23 ksi (159 MPa) (Kt=1, R.T., 500 million cycles)

· Fracture Toughness (K1c): ~25-28 MPa√m (Good for its strength level)

Functional and Processing Characteristics

· Ultra High Strength-to-Weight Ratio: 7075-T6 offers strength comparable to many steels at roughly one-third the density. This is its defining advantage.

· Good Machinability (in T6511 Temper): In the stress relieved T6511 condition, 7075 machines well, producing fragmented chips. However, its high strength demands rigid setups, sharp cutting tools, and appropriate feeds/speeds to manage cutting forces and heat generation.

· Fair Corrosion Resistance: Its corrosion resistance is generally lower than that of 6061 or 5052 due to the copper content and electrochemical nature of its precipitates. For severe environments, it is almost always used with a protective coating, such as alclad layers (thin pure aluminum coating) or anodizing (Type II or hardcoat Type III).

· Weldability: Generally considered poor for fusion welding techniques like TIG or MIG. The heat of welding destroys the carefully engineered precipitate structure in the heat-affected zone (HAZ), creating a severe loss of strength and increasing susceptibility to cracking. Joining is typically accomplished via mechanical fasteners or adhesive bonding.

· Excellent Anodizing Response: It anodizes very well, producing a hard, wear-resistant surface. Hard anodizing (Type III) is particularly common for 7075 components.

3. Mission Critical Application Scope

The property profile of 7075-T6/T6511 dictates its use in applications where performance is non-negotiable and weight savings are paramount.

A. Aerospace & Defense

· Aircraft Structures: Wing spars, stringers, fuselage frames, and landing gear components.

· Spacecraft & Satellite Components: Fittings, brackets, and structural members.

· Military Hardware: Weapon mounts, tactical equipment components, and armor plating (in specific grades).

B. High Performance Automotive & Racing

· Chassis & Suspension Components: Suspension arms, steering knuckles, and chassis braces in Formula and high-end racing.

· Drivetrain Components: Selective gearbox parts, drive shafts, and lightweight wheels.

· Prototype and Jig/Fixture Construction: For its stiffness and durability in manufacturing tooling.

C. Industrial & Sporting Goods

· Mold Tooling Plates: For plastic injection molds requiring high strength and wear resistance.

· Robotics: Critical joints, end effector adapters, and high-stress frames in dynamic robotic arms.

· High-End Sporting Equipment: Bicycle frame components (e.g., mountain bike rear triangles), rock climbing gear, and archery bows.

· Precision Shafts and Pins: For applications requiring extreme shear strength and fatigue resistance.

Why Partner with Us for Your 7075-T6/T6511 Aluminum Bar Requirements?

We transcend the role of a simple material distributor. We are your engineering ally, providing not just metal, but certified quality and manufacturing expertise.

· Assured Metallurgical Integrity: Our 7075 bars are sourced from premier mills and are fully certified to meet AMS 4120 (T6) and AMS 4121 (T6511) or ASTM B211 specifications, guaranteeing traceability and consistent, peak performance.

· Precision Machining Partnership: Leverage our integrated CNC machining capabilities. We expertly understand the machining characteristics of high strength alloys like 7075-T6511. We can transform these premium bars into complex, high tolerance finished components, ensuring dimensional stability and part integrity from start to finish.

· Expert Application Guidance: Our technical team provides more than a quote. We offer consultative support to validate that 7075 is the optimal material for your application, considering factors like stress corrosion cracking risk and required post processing, ensuring your design’s success.

When your design requires the ultimate balance of strength and weight, specify 7075-T6511. Contact our engineering support team today for detailed certification data, a competitive quotation, or a technical review of your application. Let us provide the material and manufacturing intelligence to help your most ambitious projects take flight.

Post time: Jan-27-2026