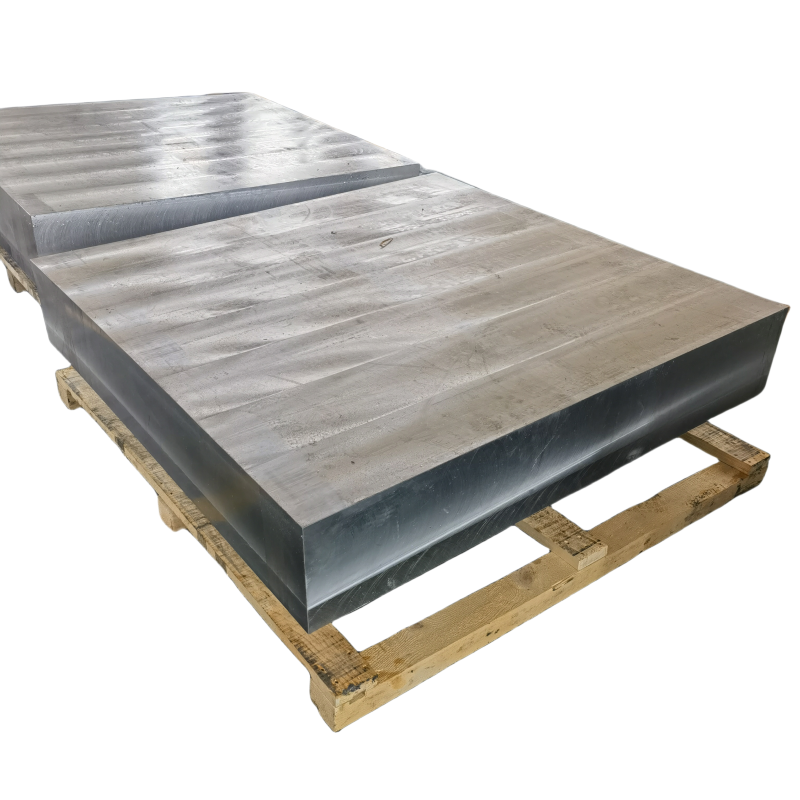

In the field of high performance materials, 7075 T6/T651 aluminum alloy sheets stand as an industry benchmark. With their exceptional comprehensive properties, they are indispensable across multiple sectors. The outstanding advantages of 7075 T6/T651 aluminum alloy sheets are primarily reflected in their remarkable strength-to-weight ratio. This characteristic stems from the precise alloy composition ratio, where zinc serves as the primary alloying element working synergistically with copper, magnesium, and chromium.

The T6 state represents a specific heat treatment process: solid solution heat treatment followed by artificial aging treatment. This process not only maintains the natural lightweight advantage of aluminum, but also significantly improves the strength performance of the material.

The T651 alloy undergoes a tempering process combining solid solution heat treatment, artificial aging, and tensile testing. Through controlled cooling and stress relief techniques, the material achieves enhanced dimensional stability, significantly reducing warping deformation during processing and service. Its exceptional corrosion resistance stands out as another key advantage. Notably, despite containing highly corrosive elements, the 7075 aluminum alloy maintains a robust alumina protective coating on its surface. This protective film effectively resists atmospheric corrosion, marine erosion, and industrial corrosion, ensuring long-term durability in harsh environments.

Mechanical properties

When it comes to mechanical prowess, the 7075 T6/T651 aluminum plate truly shines. It boasts an ultimate tensile strength typically ranging from 500 to 550 MPa. To put this into perspective, it can withstand immense forces before fracture, making it suitable for load – bearing applications. The yield strength, which indicates the stress point where permanent deformation begins, lies between 450 – 510 MPa. This high yield strength ensures the material maintains its structural integrity under substantial loads without deforming plastically.

The elongation at break is generally around 8% – 12%, reflecting a balance between strength and ductility. This moderate ductility allows for some degree of forming and machining operations without catastrophic failure. The hardness, often measured at 140 – 160 HBW (Brinell Hardness Number), provides excellent wear resistance and contributes to the material’s ability to withstand surface abrasion and indentation during service.

Broad Application Scope

The aerospace industry is perhaps the most prominent beneficiary of 7075 T6/T651 aluminum plates. They are extensively used in aircraft wings, fuselage frames, and structural components where high strength and low weight are critical for fuel efficiency and flight performance. The material’s fatigue resistance ensures it can endure the repeated stress cycles associated with take offs, landings, and in flight turbulence.

In the automotive sector, particularly in high performance and electric vehicles, these plates find applications in engine mounts, suspension components, and battery housing structures. Their strength helps in crash energy absorption while their light weight contributes to improved acceleration and energy efficiency.

The machinery manufacturing industry employs 7075 T6/T651 aluminum plates in creating precision machined components for CNC machines, industrial robots, and manufacturing equipment. The dimensional stability from the T651 temper ensures tight tolerance parts that maintain accuracy over time and extensive use.

Customized Cutting Dimensions

Understanding that each project has unique requirements, our company offers a comprehensive customized cutting service for 7075 T6/T651 aluminum plates. Whether you need precision cut rectangular plates for specific mechanical assemblies, circular discs for rotational components, or irregular shaped pieces to fit into complex machinery layouts, our advanced cutting equipment and skilled technicians can deliver with exceptional accuracy.

We utilize state of the art cutting technologies such as CNC shearing, laser cutting, and water jet cutting. Each method is selected based on the specific dimensions, tolerances, and surface finish requirements of your order. CNC shearing provides fast and clean cuts for large scale, regular shaped plates. Laser cutting offers superior precision for intricate and detailed patterns with minimal material deformation. Water jet cutting is ideal for thicknesses that might be challenging for other methods, producing edge qualities that often require little to no post processing.

Our commitment to quality extends beyond the cutting process. After cutting, each piece undergoes rigorous quality inspection. We check for dimensional accuracy using precision measuring instruments, verify the surface finish for any cutting induced imperfections, and ensure that the mechanical properties of the material haven’t been compromised during the cutting procedure.

Why Choose Our 7075 T6/T651 Aluminum Plates?

Our company stands out in the aluminum products marketplace for several reasons. First and foremost, our extensive inventory of 7075 T6/T651 aluminum plates in various thicknesses, widths, and lengths means we can often fulfill orders with shorter lead times than competitors who may need to produce or source material from scratch.

Our quality control systems are stringent and certified to international standards. Every batch of aluminum plates undergoes thorough testing for chemical composition, mechanical properties, and surface quality before it even reaches the cutting stage. This ensures that when you order from us, you’re receiving material that consistently meets the high performance benchmarks expected of 7075 T6/T651 alloy.

Our team of technical experts is always available to assist you with material selection, provide detailed specifications, and offer guidance on the most suitable cutting methods for your particular application. We understand that choosing the right material and processing techniques can be complex, especially with the wide range of aluminum alloys.Furthermore, our logistics network is designed for efficiency and reliability. Once your customized 7075 T6/T651 aluminum plates are ready, we can arrange prompt delivery to your facility, minimizing downtime in your production schedule.

The 7075 T6/T651 aluminum plate represents the pinnacle of aluminum alloy technology, combining high strength, excellent corrosion resistance, and dimensional stability. With our customized cutting services and unwavering commitment to quality, we are your ideal partner for sourcing this exceptional material. Whether you’re an aerospace manufacturer seeking to enhance aircraft performance, an automotive engineer developing the next generation vehicle, or a machinery builder requiring precision engineered components, our 7075 T6/T651 aluminum plates will exceed your expectations and contribute to the success of your projects.

Post time: Jul-18-2025