In the vast landscape of aluminum alloys, some are engineered for raw strength, others for extreme machinability. Then there is 6063. Often hailed as the “architectural alloy,” 6063 aluminum is the premier choice for applications where aesthetics, formability, and corrosion resistance are paramount. While most commonly associated with extruded shapes, its availability in plate form opens a world of possibilities for specific fabrications. This article delves into the specifics of 6063 aluminum plate, its properties, and its practical industrial applications.

6063 aluminum belongs to the Al-Mg-Si series, a class of alloys known for their excellent extrudability and good mechanical properties. Its chemical composition is precisely balanced:

· Magnesium (Mg): 0.45-0.9% – Enhances strength through solid solution hardening.

· Silicon (Si): 0.2-0.6% – Works in tandem with magnesium to form the intermetallic compound Magnesium Silicide (Mg2Si), which is the primary contributor to the alloy’s strength during heat treatment.

This specific balance makes 6063 exceptionally responsive to heat treatment, specifically the T5 and T6 tempers. The process involves solution heat treatment, quenching, and artificial aging to achieve its peak strength characteristics. While its tensile strength is moderate compared to alloys like 6082 or 7075, this is a deliberate trade-off for vastly superior surface finish and extrusion capabilities.

The value of 6063 aluminum plate lies in its unique combination of properties:

· Superb Surface Finish: This is arguably its most celebrated feature. 6063 is renowned for its ability to accept and retain a brilliant, high-quality surface finish. It is exceptionally suited for anodizing, which dramatically enhances its corrosion resistance and allows for a wide range of durable, cosmetic colors. Powder coating and painting are also highly effective.

· Excellent Corrosion Resistance: The alloy demonstrates very good resistance to atmospheric corrosion, rivaling that of the 5000 and other 6000 series alloys. This makes it ideal for both indoor and outdoor applications without requiring heavy protective coatings.

· High Formability and Workability: In its annealed (“O” temper) state, 6063 plate offers good ductility and can be bent and formed with relative ease. Its machinability is considered fair to good; while it machines cleaner than many softer alloys, its slightly abrasive nature due to the Mg2Si particles recommends using sharp, positive-rake tools.

· Moderate Strength: In the T6 temper, 6063 plate typically achieves a tensile strength of around 241 MPa (35 ksi) and a yield strength of 214 MPa (31 ksi). This makes it suitable for structural applications where high loads are not a primary concern.

The application range for 6063 aluminum plate is extensive, leveraging its aesthetic and functional strengths:

· Architectural and Building Products: This is its core domain. It is extensively used for decorative panels, trim, fascia systems, and door and window components. Its ability to be beautifully anodized makes it perfect for modern building exteriors and interiors where appearance is critical.

· Consumer Goods and Furniture: The demand for sleek, modern, and lightweight designs has made 6063 a favorite. It is fabricated into frames for furniture, home appliances, display units, and recreational equipment. Its corrosion resistance ensures longevity, even in everyday use.

· Automotive Trim and Details: Beyond structural parts, the automotive industry utilizes 6063 for trim pieces, radiator grilles, and decorative brackets where a high-quality surface finish is non-negotiable.

· Heat Sinks: While often extruded, 6063 plate can be machined into custom heat sinks for electronic applications. Its excellent thermal conductivity (approximately 209 W/m·K) is a key advantage here.

· Marine Fit-Outs: For interior boat and ship components like railings, trim, and non-structural panels, 6063 offers the perfect blend of saltwater corrosion resistance and aesthetic appeal.

Why Partner With Us for Your 6063 Aluminum Plate Needs?

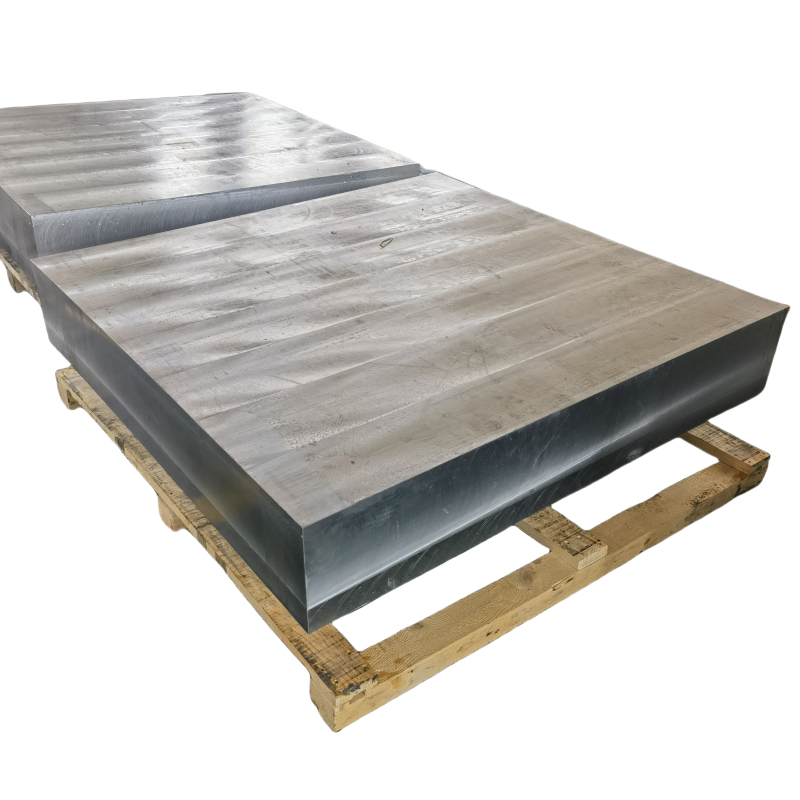

Our expertise extends beyond merely supplying raw material. We understand the nuances of alloys like 6063. We provide precision-sheared and saw-cut 6063 plates tailored to your project dimensions. Furthermore, our advanced CNC machining services can transform these plates into finished, ready-to-assemble components, saving you time and reducing production complexity.

6063 aluminum plate is the definitive solution for projects where visual appeal, corrosion resistance, and formability are the driving factors. It may not be the strongest alloy, but it is undoubtedly one of the most versatile for aesthetic-driven fabrication.

Post time: Sep-09-2025