Data released by China’s National Bureau of Statistics confirms a year of steady expansion for the nation’s non-ferrous metals sector, with primary aluminum production being a core component of this growth. Annual output of primary aluminum (electrolytic aluminum) reached 45.02 million tonnes in 2025, marking a 2.4% increase compared to the previous year. The industry maintained positive momentum through December, with monthly production hitting 3.87 million tonnes, a 3.0% year-on-year rise.

This performance occurred within a broader context of sector wide strength. The value-added output of non ferrous metal smelting and rolling industries grew by 6.8% cumulatively from January to December. Production of ten key non ferrous metals, a category that includes aluminum, totaled 81.75 million tonnes for the year, reflecting a 3.9% cumulative increase.

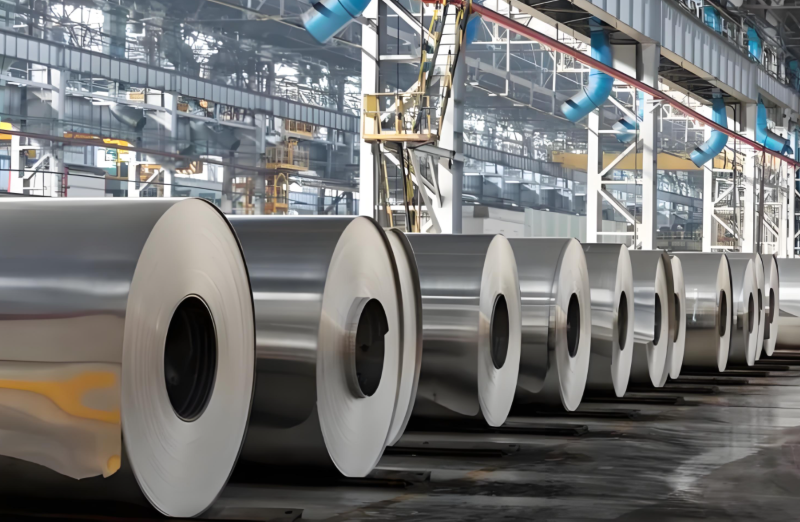

The consistent rise in primary aluminum production is a critical indicator for downstream fabricators and engineering firms. It signifies stable and ample raw material availability, which is fundamental for production planning, cost management, and ensuring consistent metallurgical properties in finished products. This reliable upstream supply allows processors to focus on value-added activities and meet complex client specifications.

Our company operates at this crucial intersection of stable supply and advanced manufacturing. We specialize in transforming primary aluminum into high precision, semi fabricated products. Our core offerings include custom sized aluminum plate, extruded bar and rod stock, and drawn tubing, all engineered to meet specific dimensional and alloy requirements for diverse industrial applications.

Beyond supplying these essential forms, our technical expertise is fully realized through our comprehensive in-house machining capabilities. We provide precision CNC machining, milling, cutting, and finishing services, delivering ready-to-install components that integrate directly into our clients’ assemblies. This integrated approachfr om selecting the right alloy based on application needs to delivering a final machined part ensures exceptional quality control, reduces supply chain complexity, and provides significant value for sectors such as industrial machinery, transportation, and structural engineering.

The sustained growth in China’s primary aluminum output provides a solid foundation for the entire manufacturing ecosystem. It enables partners like us to guarantee material consistency and leverage our processing expertise to deliver reliable, customized aluminum solutions.

Post time: Jan-21-2026