Lizhong Group has achieved another crucial milestone in the global game of aluminum alloy wheels. On July 2nd, the company disclosed to institutional investors that the land for the third factory in Thailand has been purchased, and the first phase of the 3.6 million ultra lightweight wheels project in Monterey, Mexico has officially started production. The second phase plans to release production capacity in the third quarter of 2025. This series of actions not only strengthens its “Thailand+Mexico” dual core driven production capacity map, but also deeply embeds China’s high-end manufacturing tentacles into the global new energy vehicle industry chain, providing a new paradigm for addressing trade barriers and industrial upgrading.

Southeast Asian manufacturing base: from cost depression to technological highland

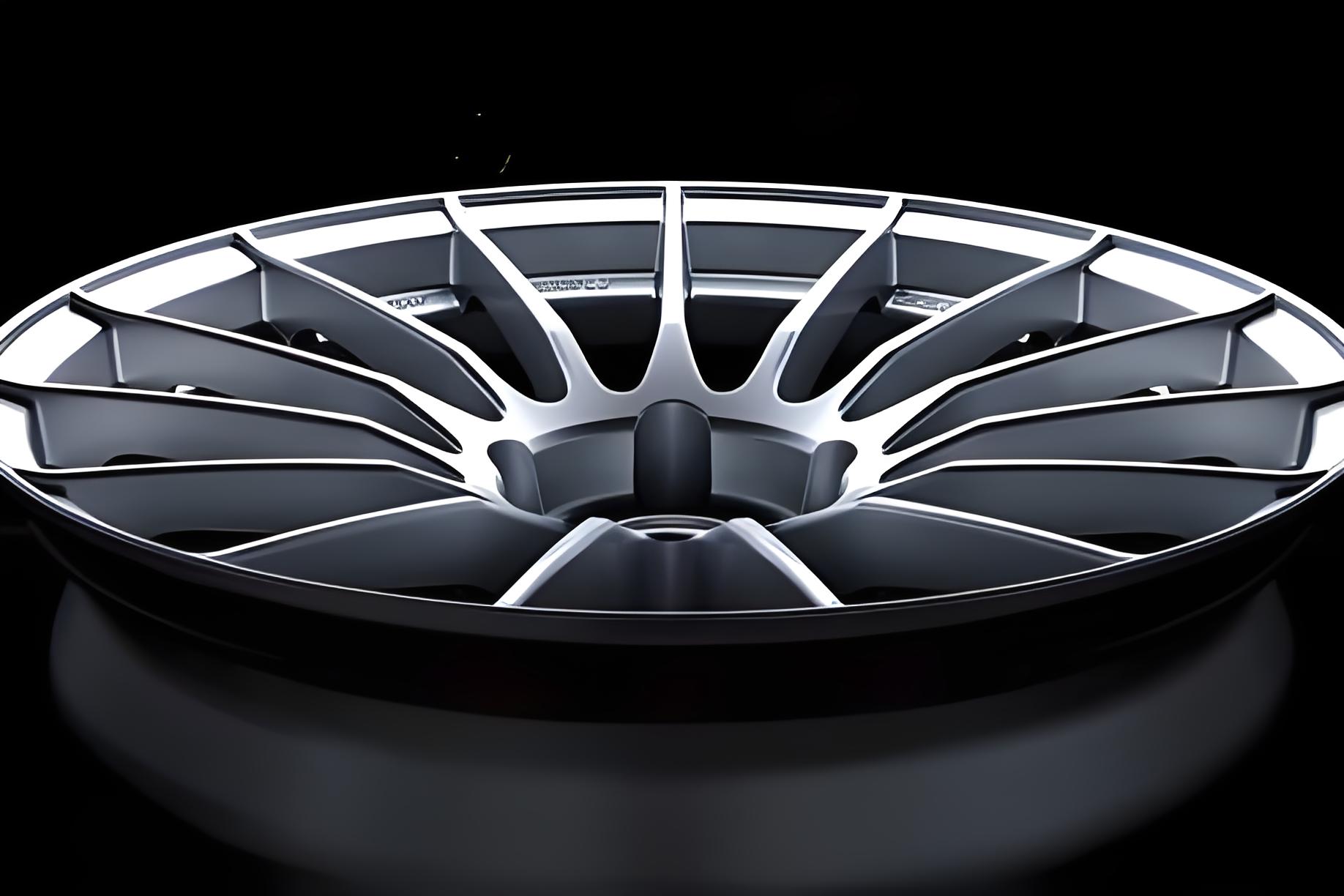

The layout of Lizhong Group in Thailand far exceeds the traditional logic of capacity expansion. The newly purchased land and factory buildings will be used to build integrated research and development centers and intelligent factories, with a focus on breakthroughs in lightweight technology for new energy vehicle specific wheels. After the third factory in Thailand is put into operation, the local production capacity will increase to 8 million units per year, in line with the local government’s subsidy policy for new energy vehicles (with a maximum subsidy of 150000 Thai baht per vehicle), which can radiate to Southeast Asian and European markets. It is worth noting that the spinning forging composite process production line introduced by the company has achieved a yield strength of 420MPa for the wheel hub, which is 60% higher than traditional casting processes and directly benchmarks the standards of high-end European car models.

Mexico’s Capacity: A ‘Nearshore Strategy’ to Break the North American Trade Dilemma

The first phase of the Monterrey project in Mexico has achieved full production capacity of 1.8 million units, and the products are mainly supplied to North American car companies such as Tesla and General Motors. After the second phase is put into operation, the total production capacity will reach 3.6 million units, which can cover 30% of the lightweight wheel hub demand in the US market. The base adopts a “nearshore manufacturing+localized procurement” model: 60% of the aluminum comes from local suppliers in Mexico (saving 12% tariffs compared to imports from China), and 40% of the recycled aluminum comes from recycling centers in the southwestern United States, forming a dual barrier breakthrough of “zero tariffs+low-carbon certification”. CITIC Securities estimates that this production capacity layout can reduce the comprehensive cost of exporting North American products by 18% and increase the gross profit margin by 5-7 percentage points.

Industrial Undercover War: Technological Challenges in the Global Capacity reshuffle

The aggressive expansion of Lizhong Group reflects that the aluminum alloy wheel industry is undergoing profound changes:

EU anti-dumping upgrade: In June 2025, the EU imposed a 19.6% tariff on Chinese aluminum alloy wheels, forcing Chinese companies to accelerate the transfer of production capacity to Southeast Asia and Mexico;

Tesla Supply Chain Restructuring: The Model Y facelift model requires a 15% reduction in wheel weight. The magnesium aluminum composite wheel hub customized and developed by Lizhong Group has been verified by Tesla and is expected to enter mass production in 2026;

Competition for dominance in technical standards: The group standard “Recycled Aluminum Gold for New Energy Vehicle Wheel Hubs” developed by the company will be implemented in September, directly benchmarking against international ISO standards.

Risk and opportunity coexist: the game between overcapacity and technological iteration

Although globalization has opened up growth opportunities, industry concerns cannot be ignored: the utilization rate of domestic aluminum alloy wheel production capacity has dropped to 68% (2024 data), and the surge of new entrants in Southeast Asia may lead to regional overcapacity. The strategy of Lizhong Group is “technology premium+service value-added” dual wheel drive – its developed intelligent wheel hub (integrated tire pressure monitoring and load sensing) has won Michelin’s high-end modification order, with a single unit price increase of 300% compared to traditional products.

The Dual Narrative of Capital Markets

The focus of institutional investors on the opposition group is showing differentiation: long-term funds such as Tianhong Fund are optimistic about the penetration of its Mexican production capacity into the North American market, while institutions such as Cinda Securities are more concerned about the construction of patent barriers in Thailand’s R&D center. It is worth noting that the company’s ongoing recycled aluminum closed-loop project (with an aluminum recovery rate of 98%) will receive a green premium of 120 euros per ton if it passes the EU carbon tariff certification.

As the automotive industry moves from electrification to intelligence, aluminum alloy wheels are evolving from “functional components” to “data carriers”. The global production capacity bottleneck of Lizhong Group is not only a breakthrough from traditional manufacturing to high-end intelligent manufacturing, but also a microcosm of China’s high-end equipment going global. This industrial revolution, which began with the wheels, may be reshaping the power structure of the global automotive supply chain.

Post time: Jul-04-2025